Reflective-Mode Planar Microwave Sensors: Sensitivity & Selectivity Optimization Using Advanced Techniques & Artificial Intelligence

Follow the presentation on your device

Personal & Institutional Context

- University Teacher Training Fellowship FPU20/05700 (2021–2025);

≈180 hours of teaching microwave and electronics labs & problem solving - Research stay: University of British Columbia in Canada (AI-enabled sensing)

- Industry Projects:

- Smart Cellar CPP Project (Garcia Carrion)

- Corrosion detection in urban lighting poles (RUBATEC)

- National Research Projects:

- PID2019-103904RB-I00 (Design and synthesis of RF/microwave devices...)

- PID2022-139181OB-I00 ($\mu$WAVE-SENS)

- External Projects:

- AI4ALL 2023 Winner team (Real world applications of AI)

- AI Accelerator 2023 Mobile World Congress (Continuation of AI4ALL)

- Outcomes: thesis contributions (11 compendium articles + 7 works) + tech transfer (agrifood, structural health monitoring, future hospital pilots)

Outline

- I. Thesis Objectives

- II. Fundamentals

- III. Sensitivity Enhancement

- IV. AI-Driven Sensing

- V. Applications & Discussion

- VI. Future Work & Conclusions

Thesis Objectives

The Problem: Sensitivity vs Selectivity

Analogy: Smoke Detector

Sensitive to smoke (toast or fire?)

Discern type of smoke

The Goal: Sensitive & Selective Sensing

Thesis Objectives

-

Sensitivity & Size Optimization

Maximize sensitivity per unit area. -

Liquid Measurement & Automation

Reliable characterization of fluids. -

AI-Enabled Sensing Modalities

Selectivity and remote sensing via ML.

Fundamentals

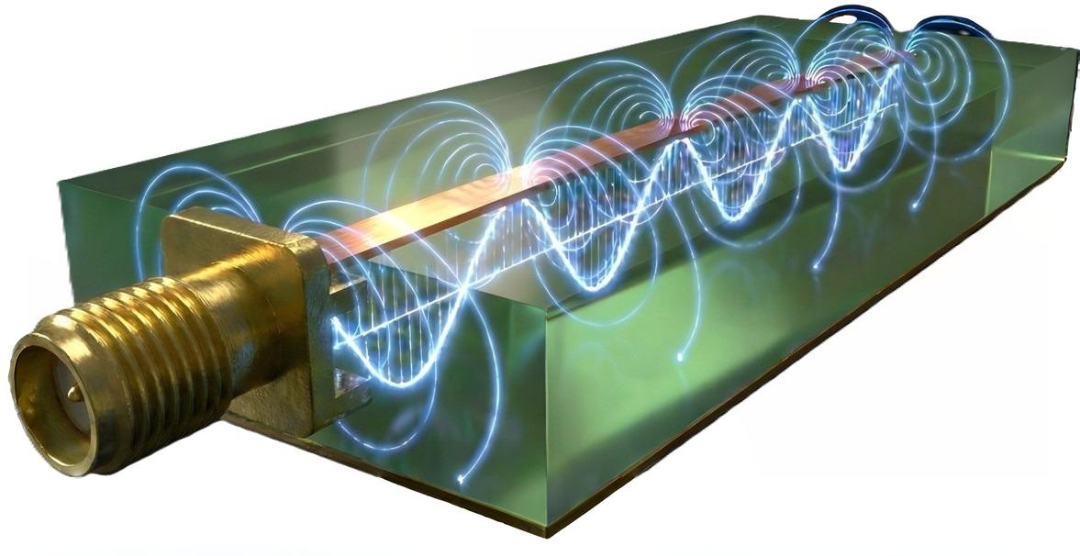

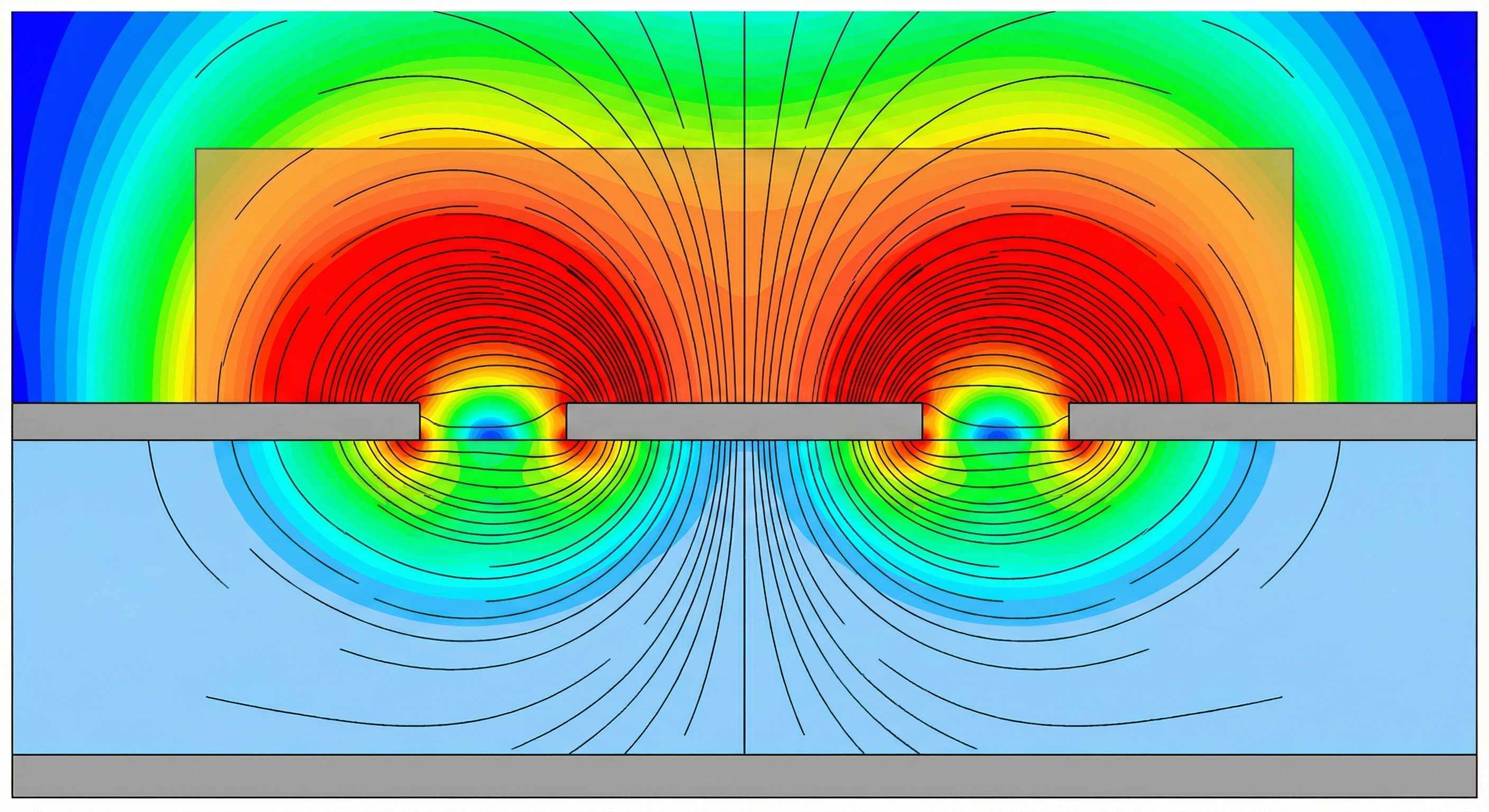

Planar Technology

Guiding Waves

- Microstrip & CPW lines

- Confines field to a specific region

Benefits

- Controllability

- Low Cost

- Easy Fabrication (CNC)

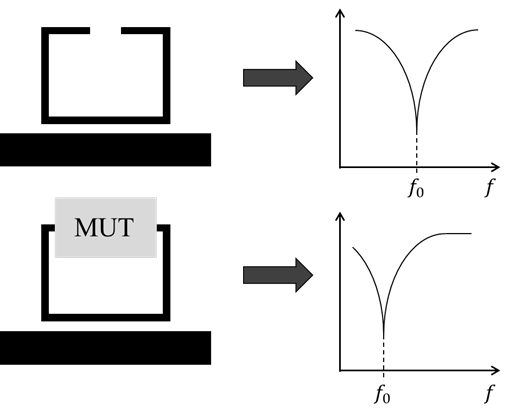

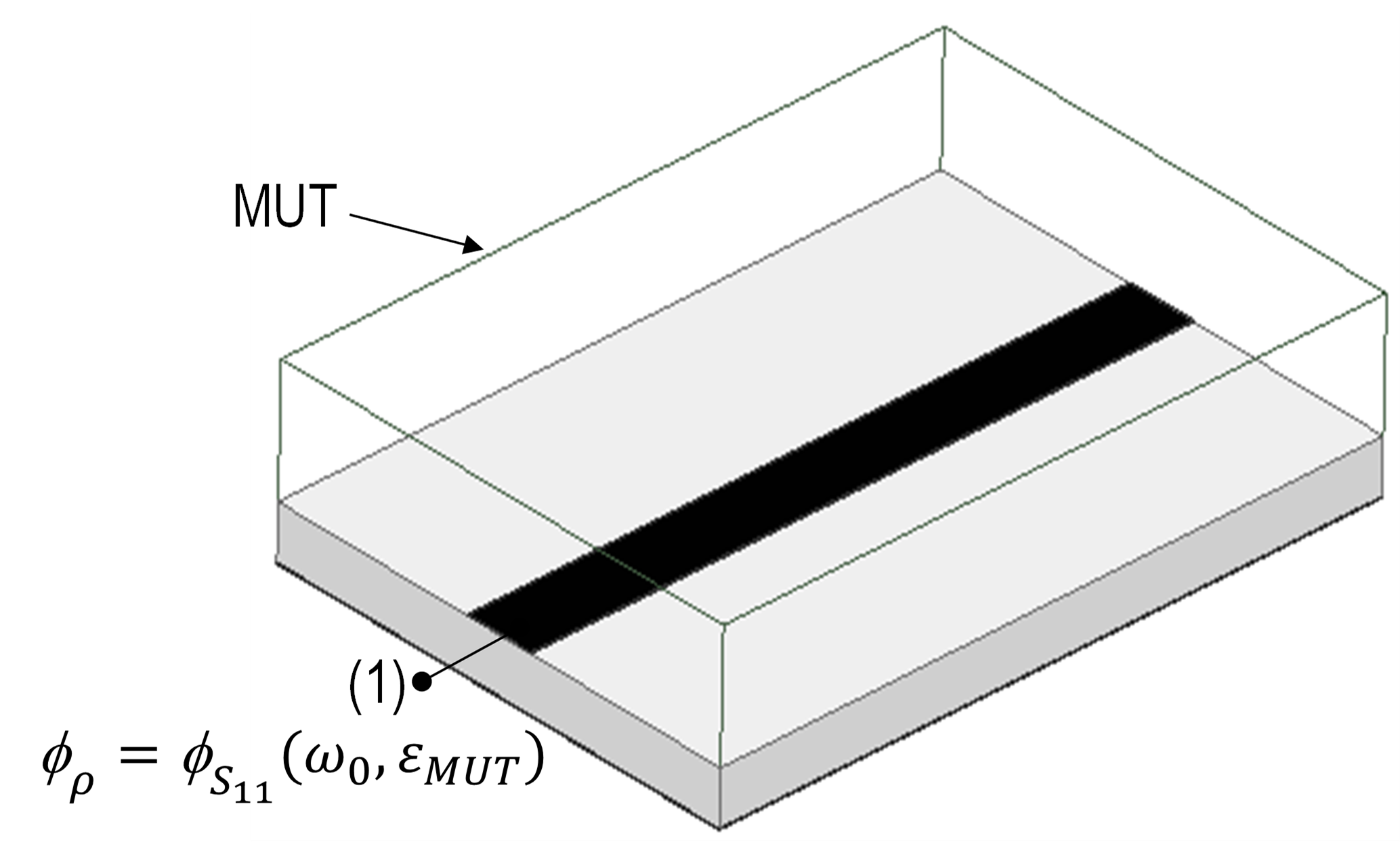

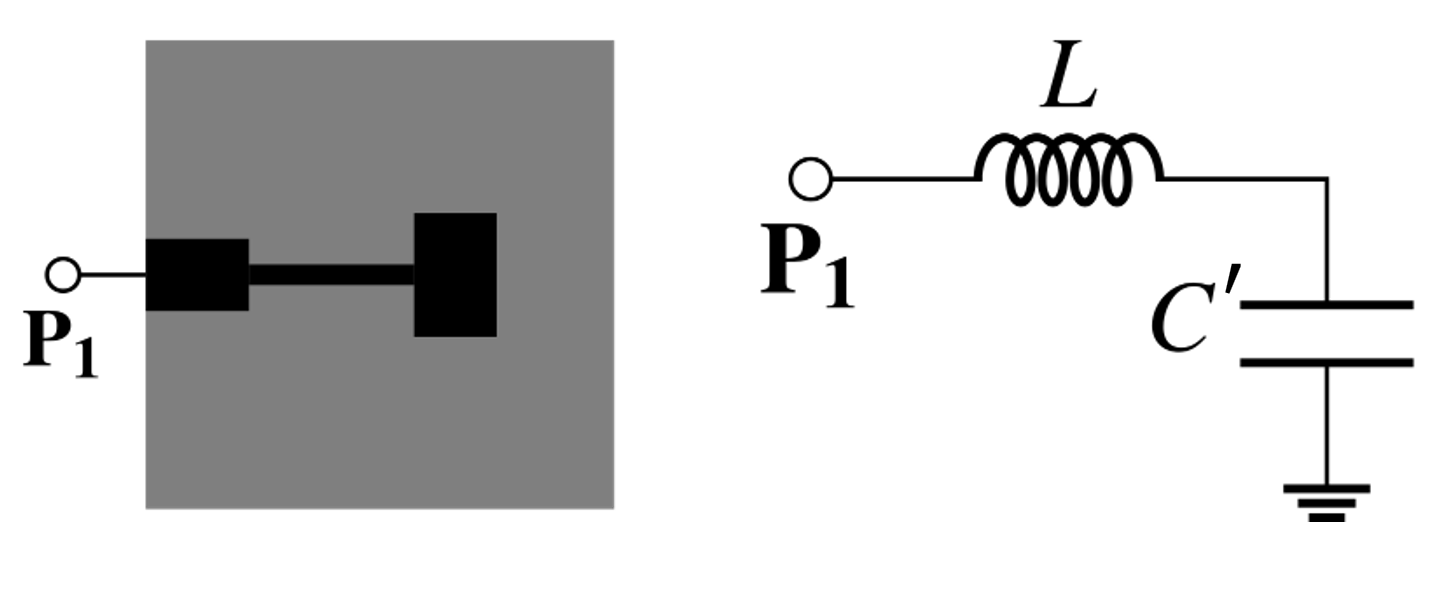

Resonators

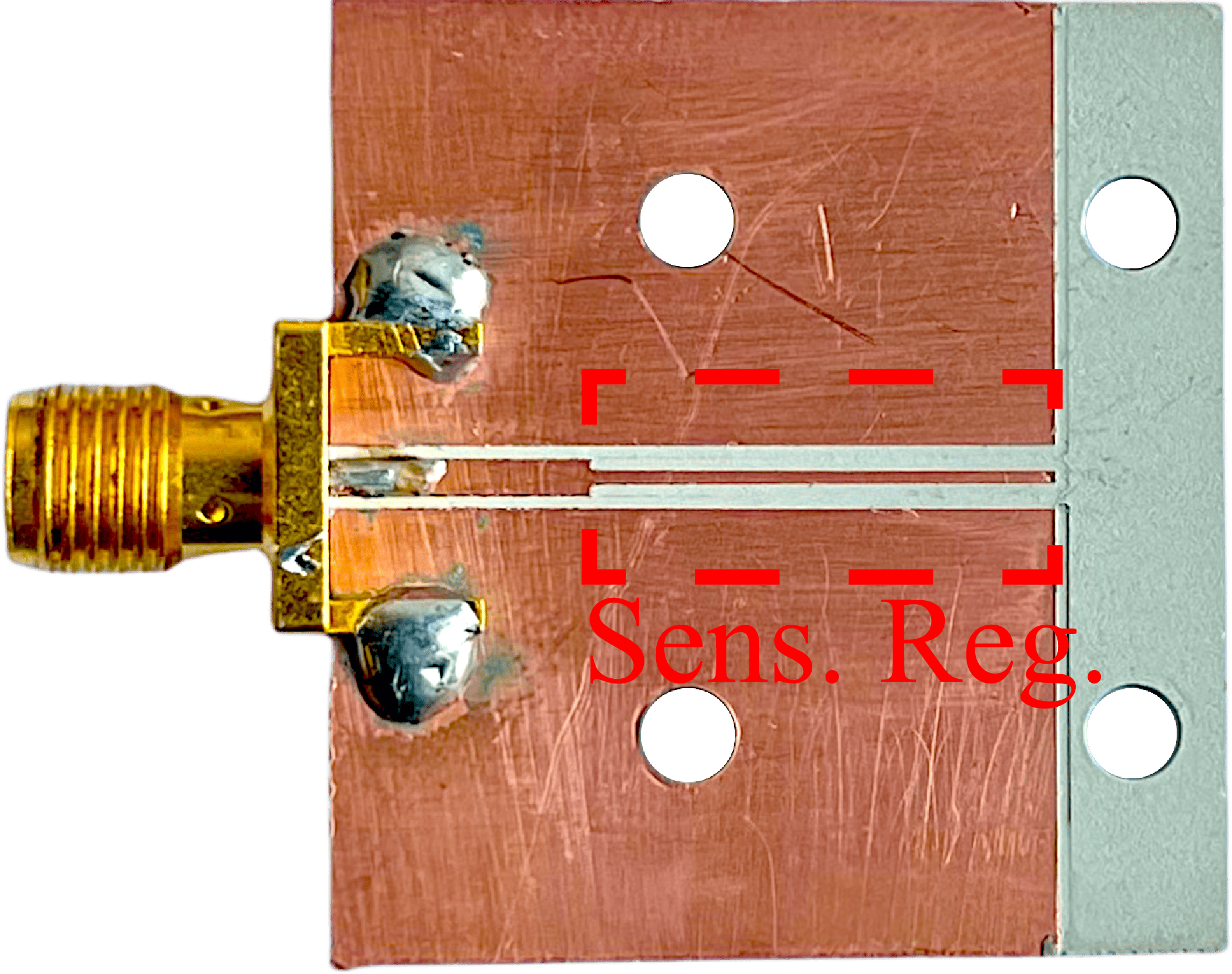

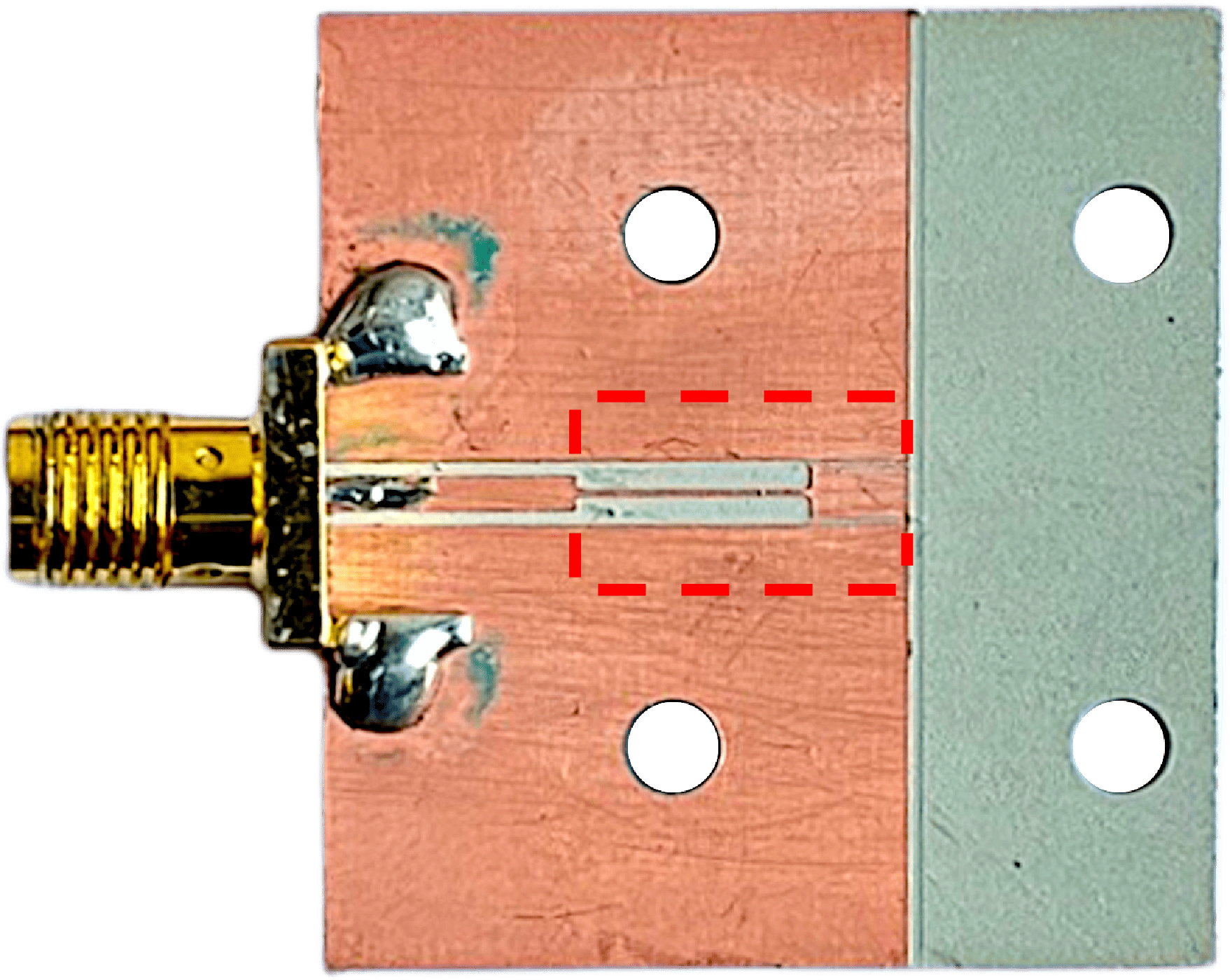

- Sensing Region: Where field interacts with MUT (Material Under Test).

- Resonance: High sensitivity to dielectric changes.

- Topology: Can be shaped to optimize interaction.

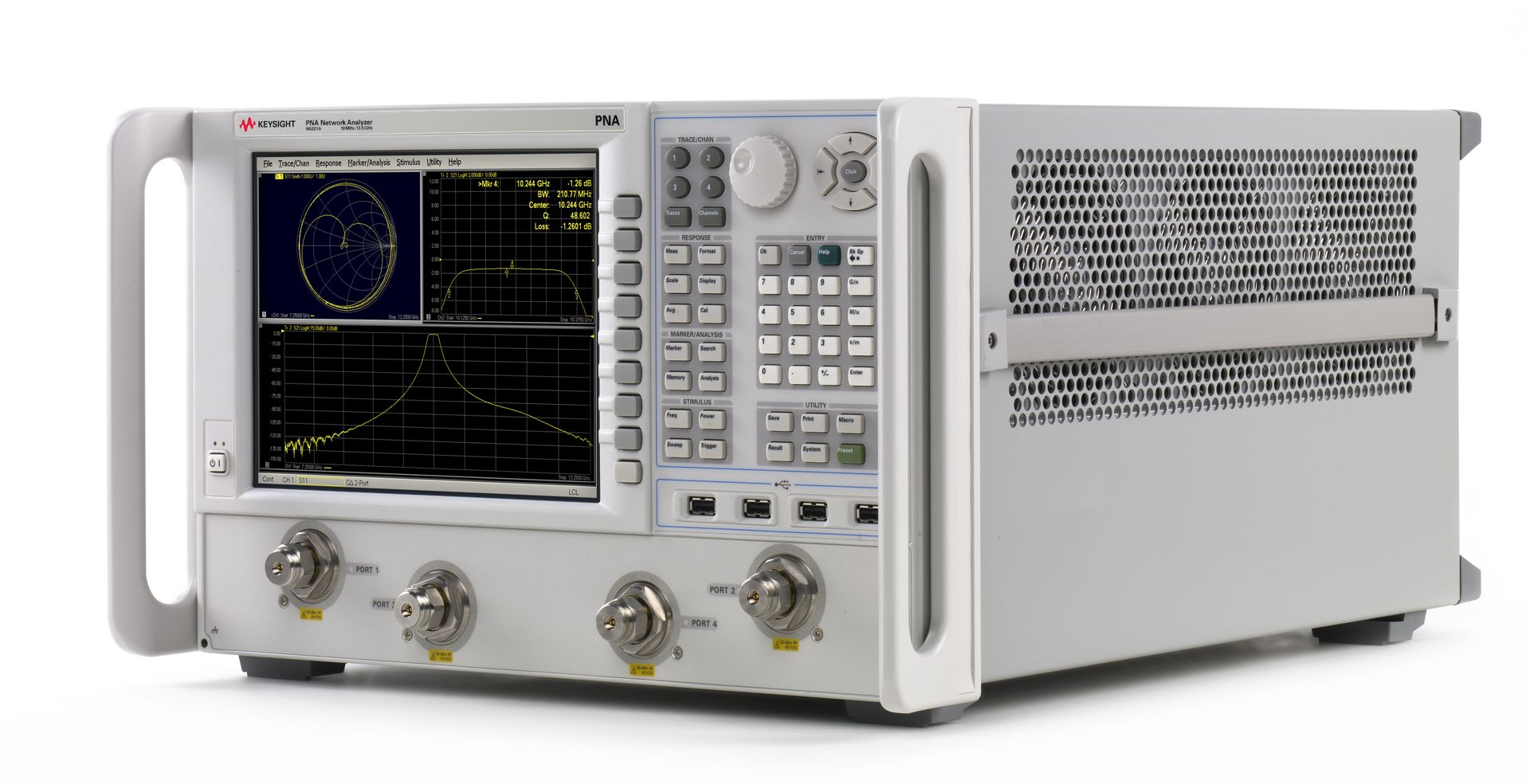

Measurement: VNA

- Vector Network Analyzer (VNA): The "instrumental" part of the measurement.

- Function: Generates signal and analyzes reflection and transmission.

- Parameter: Reflection ($\rho$) and Transmission ($\tau$) Coefficients.

Frequency Variation Sensors

- Principle: Resonance frequency shift caused by MUT.

- Pros: Simple structure but complex readout.

- Cons: Spectrum analysis required for measurement.

Magnitude Variation Sensors

- Principle: Variation in Q-factor or peak/notch attenuation.

- Pros:

- Simple scalar readout.

- Single frequency operation.

- Cons: Susceptibility to noise.

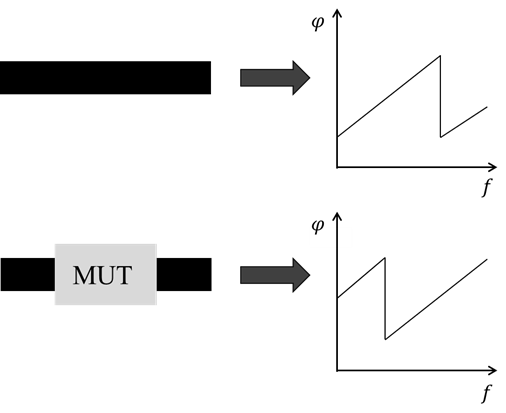

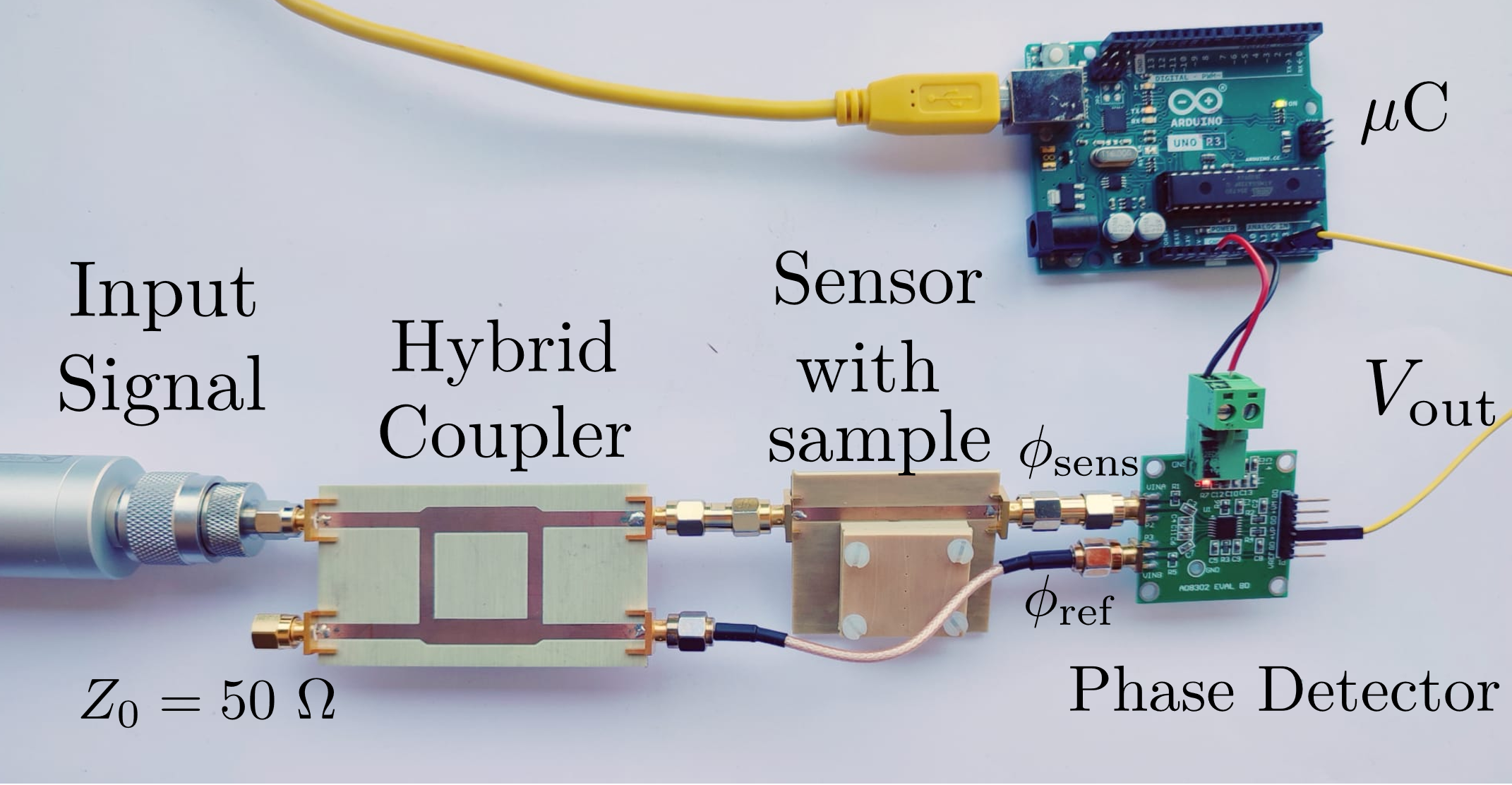

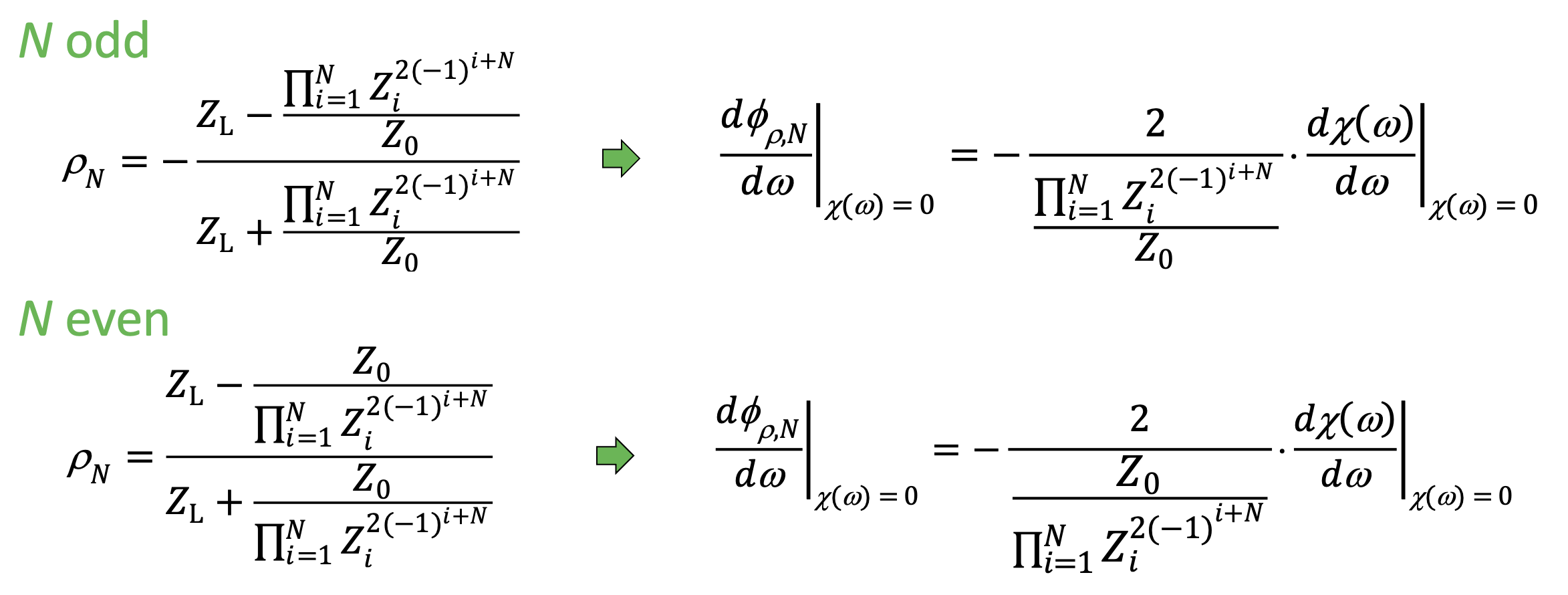

Phase Variation Sensors

- Principle: Phase shift at a single frequency.

- Pros:

- Single frequency operation.

- Robust against EMI.

- Cons: Trade-off between size and sensitivity (requires long lines).

Readout Strategy

- Single Frequency Operation:

- Focus on one frequency where sensitivity is highest.

- Reduces readout complexity and cost.

- Accessibility:

- From Lab Equipment to Portable Devices (LiteVNA ~100€).

- Low cost phase detector (AD8302 ~5€).

Sensitivity Enhancement

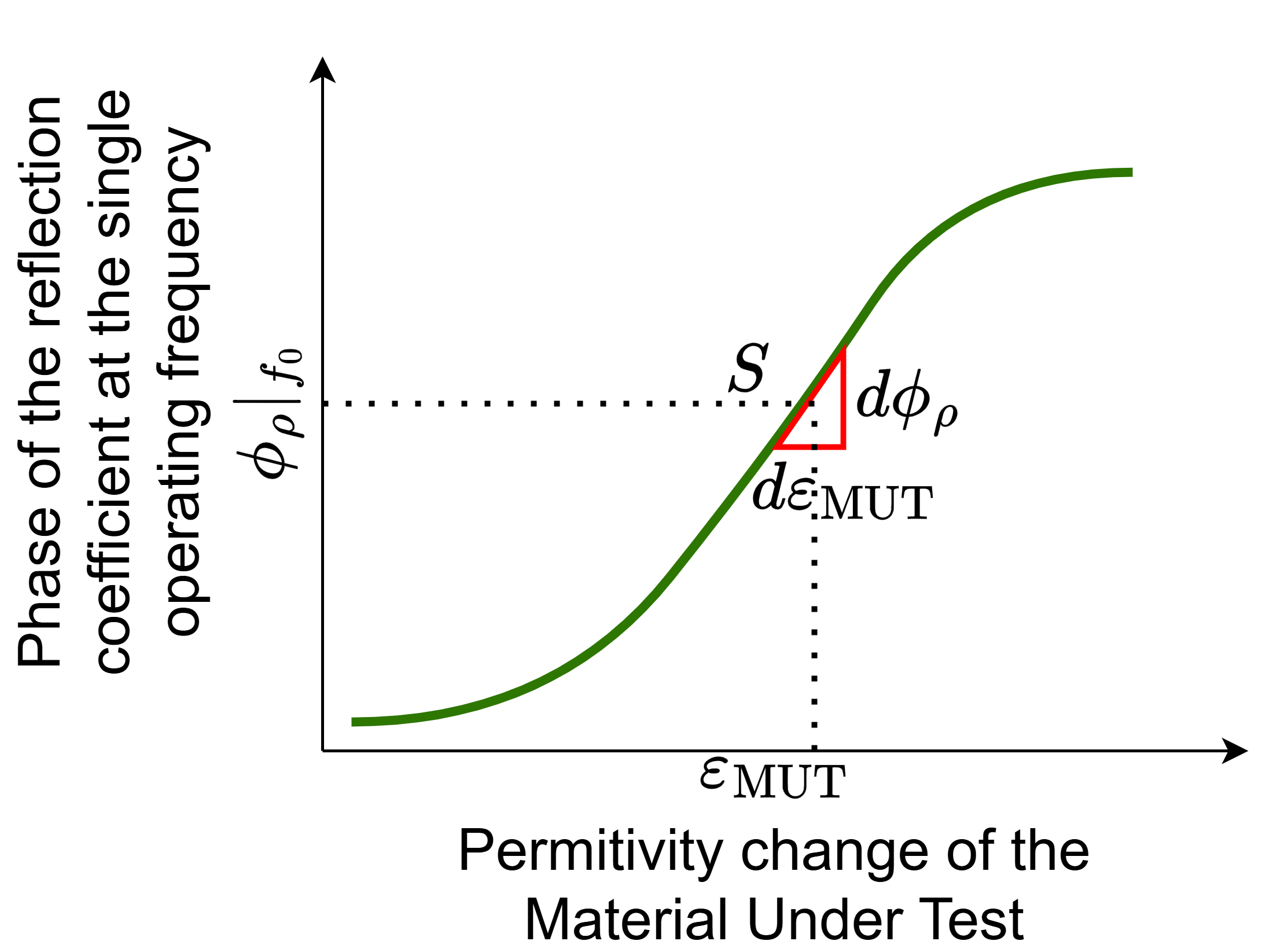

Defining Sensitivity

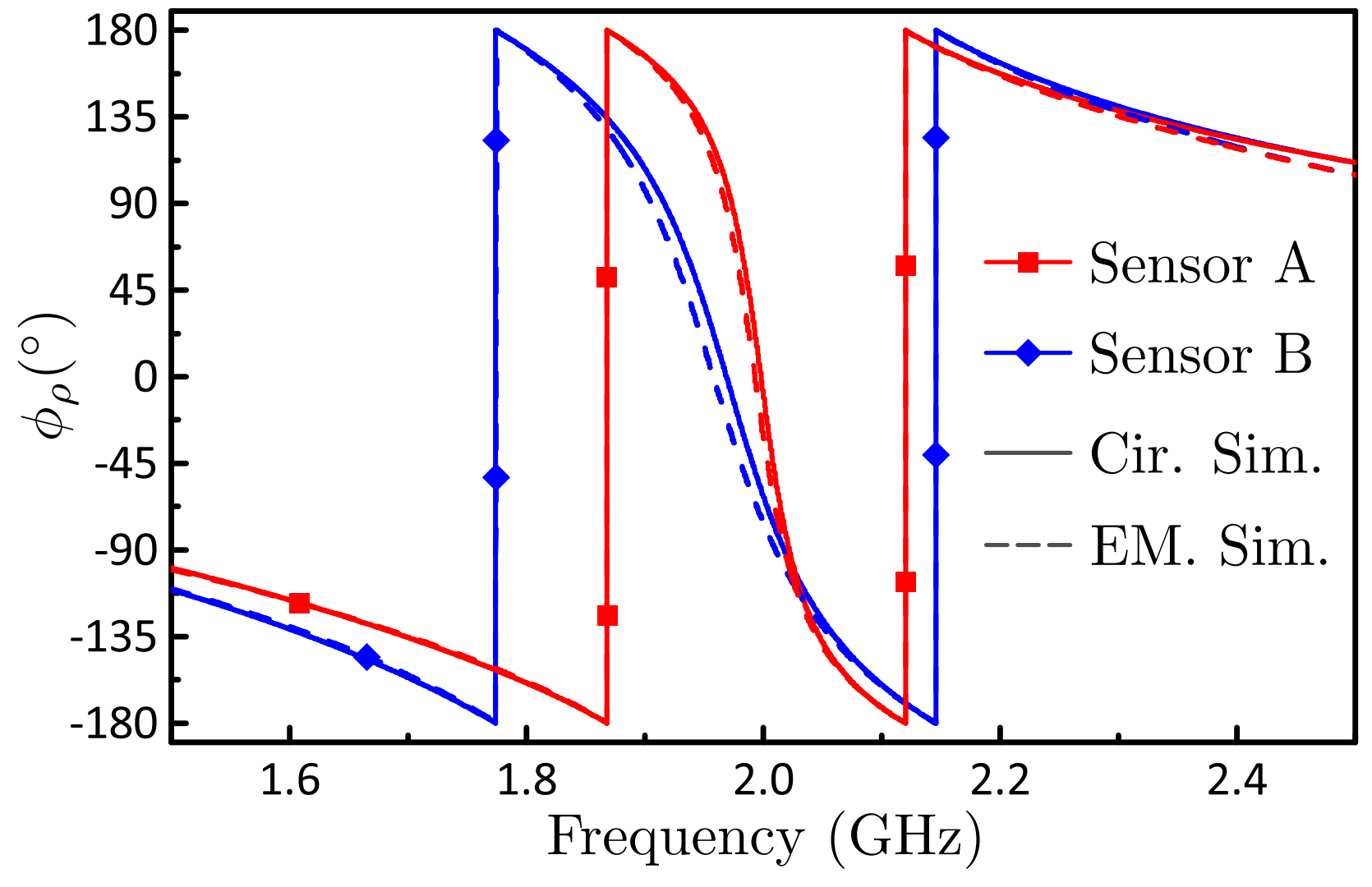

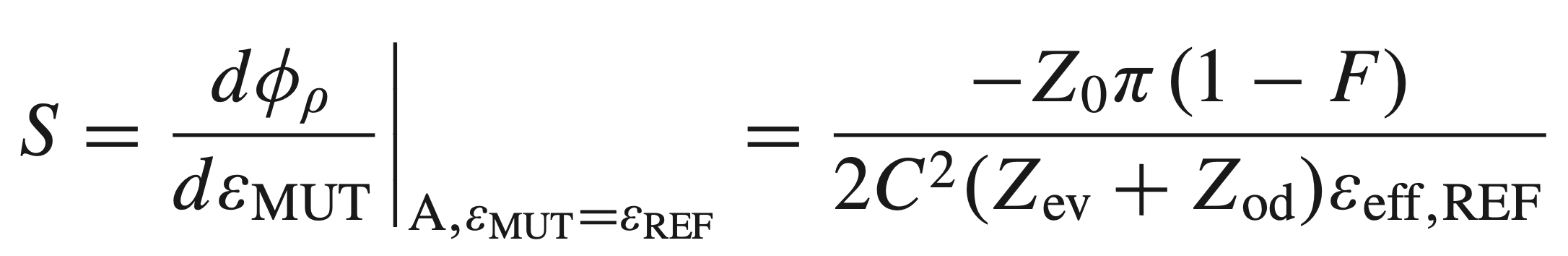

Sensitivity ($S$) is defined as the change in the phase of the reflection coefficient ($\phi_\rho$) per unit change in permittivity ($\varepsilon_\mathrm{MUT}$).

$ S = \frac{d\phi_\rho}{d\varepsilon_\mathrm{MUT}} $

Sensitivity Decomposition

We can decompose sensitivity into two independent factors:

$ S = \underbrace{\frac{d\phi}{d\upsilon}}_{\text{Electrical Transformation}} \cdot \underbrace{\frac{d\upsilon}{d\varepsilon_\mathrm{MUT}}}_{\text{Field Interaction}} $

Field Interaction ($\frac{d\upsilon}{d\varepsilon_{MUT}}$)

- Physics: How the electric field penetrates the material.

- Optimization:

- Maximize field concentration.

- Use thin substrates or CPW structures.

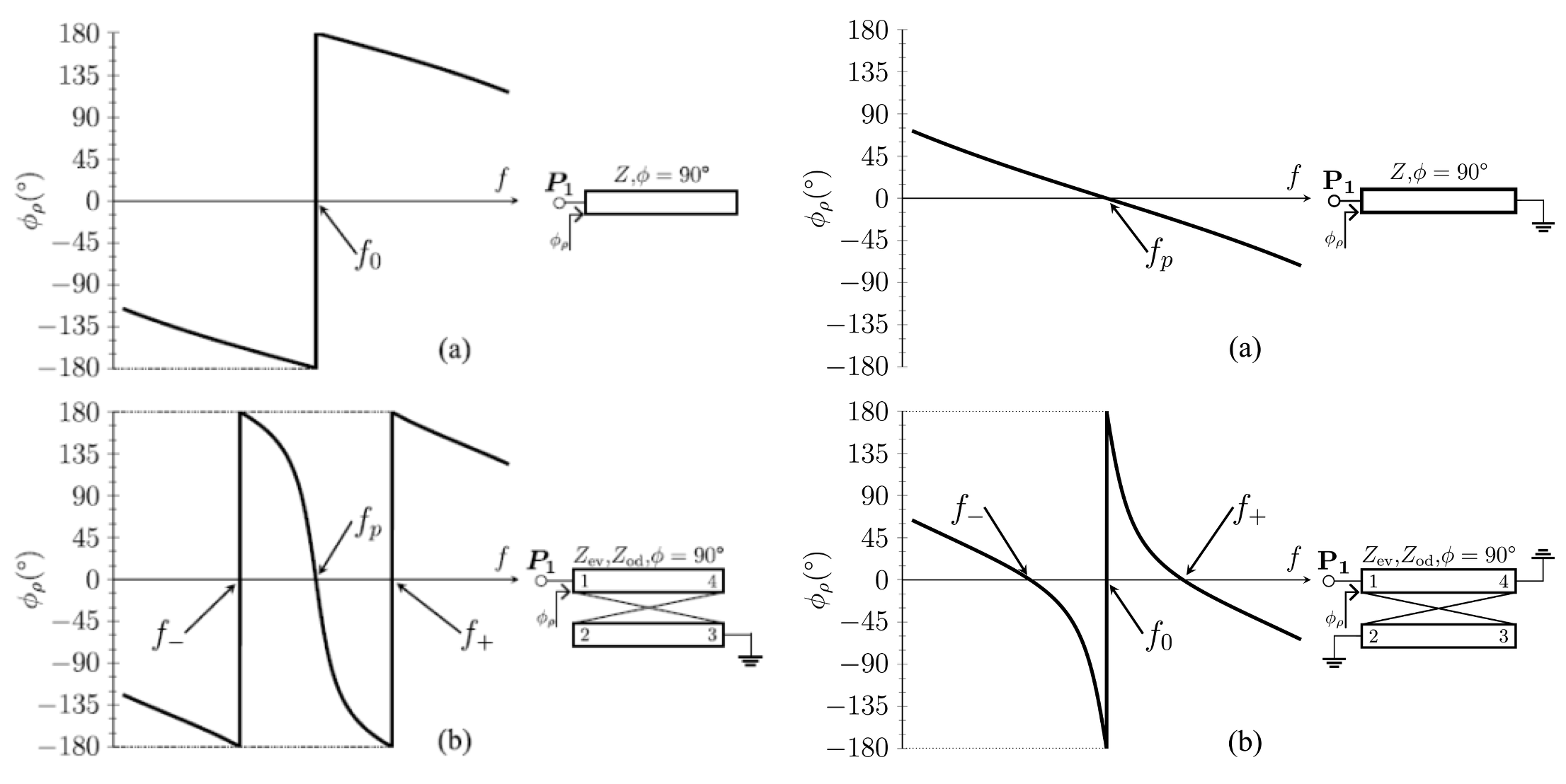

Electrical Transformation ($\frac{d\phi}{d\upsilon}$)

- Circuit: How the sensor circuital elements converts parameter change to phase shift.

- Optimization:

- Phase Slope Enhancement Techniques.

- This is the term where we can gain orders of magnitude!

Four Ways to Increase Sensitivity

1. High/Low Impedance Inverters

Cascading phase shifters, increasing overall sensor area.

2. Weakly Coupled Resonators

Exploiting split resonances due to low coupling, sensing region.

3. Resonance-Antiresonance

Smallest sensing region, dynamically tunable coupling.

4. Loss Engineering

Using loss as a design parameter, compatible with previous techniques.

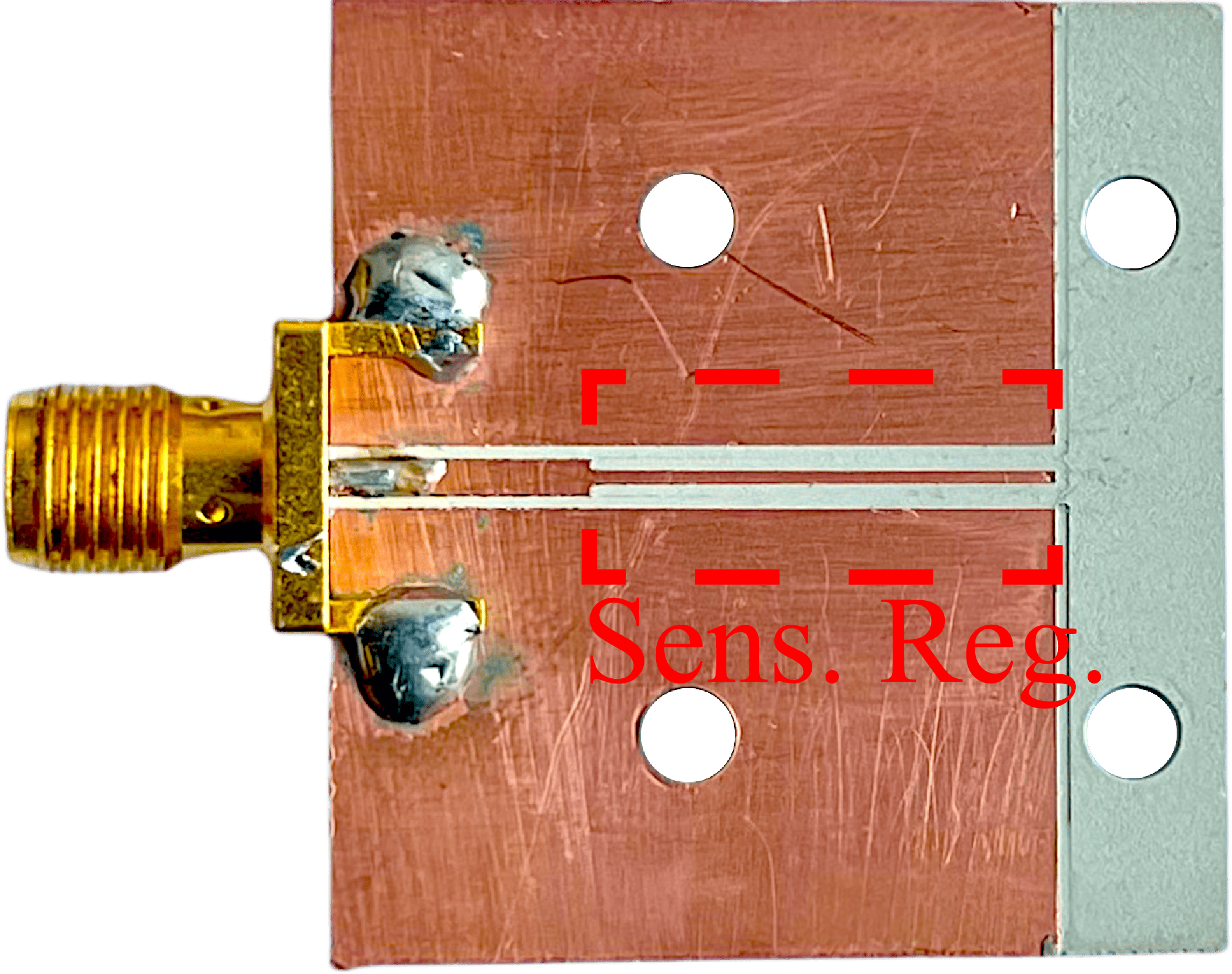

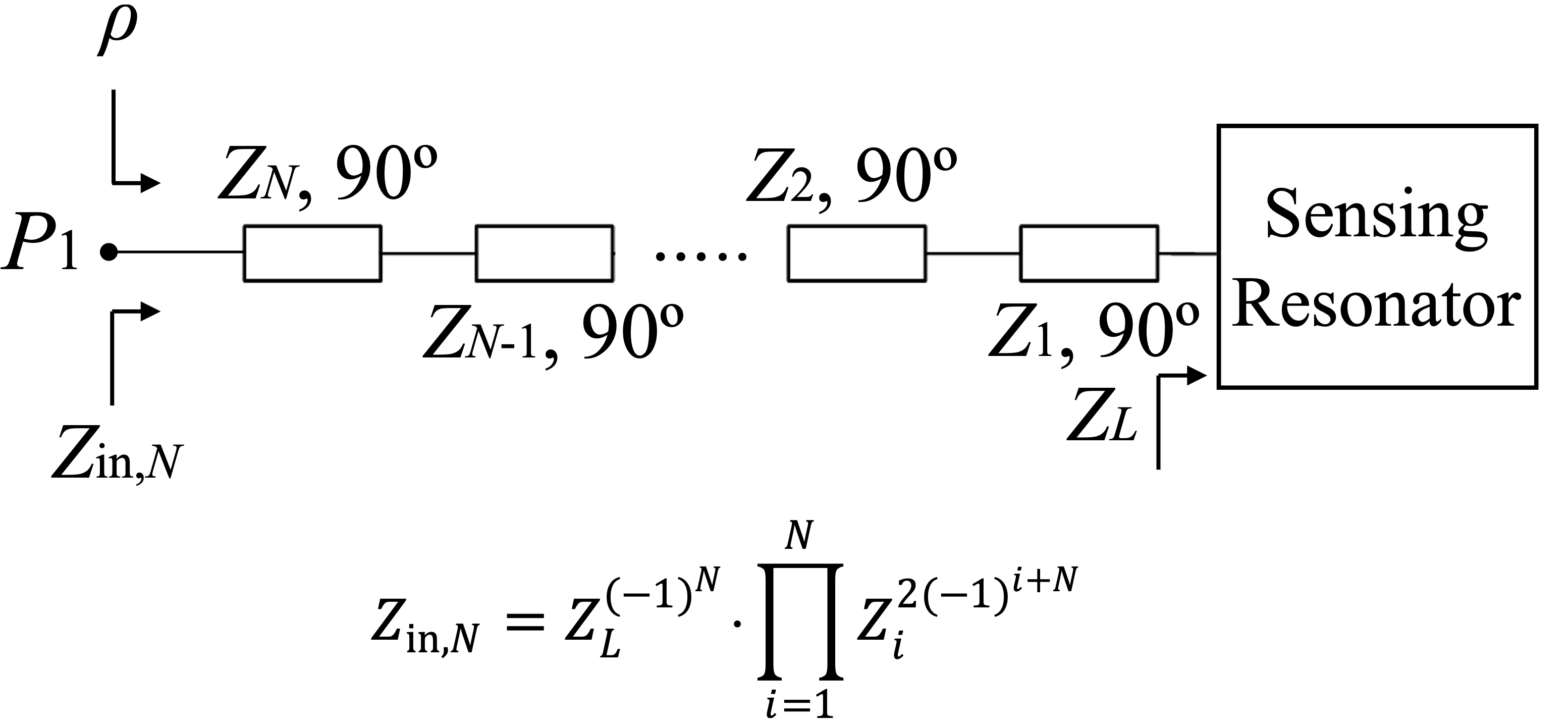

1. High/Low Impedance Inverters

Concept: Cascading 90° transmission lines (inverters) with high/low impedance to multiply the phase slope.

Inverters: Implementation

- Structure: Stepped Impedance Resonator (SIR) + Inverters.

- Goal: Reduce size while maintaining the "multiplied" slope.

- Result: High sensitivity in a compact footprint.

Inverters: Results

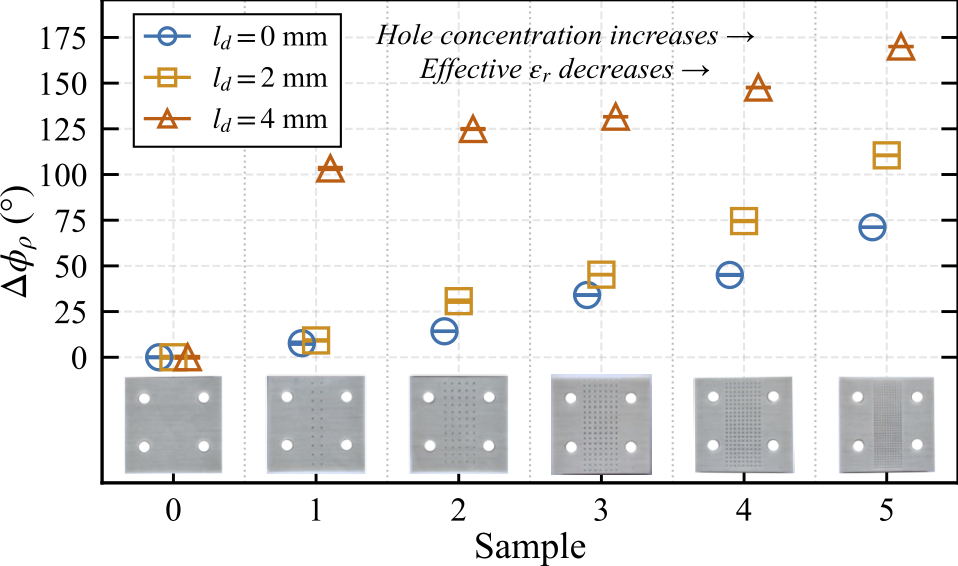

- Validated with perforated dielectric samples.

- Outcome: Sensitivity scales with the number of inverters.

- Limitation: Size grows with each inverter stage.

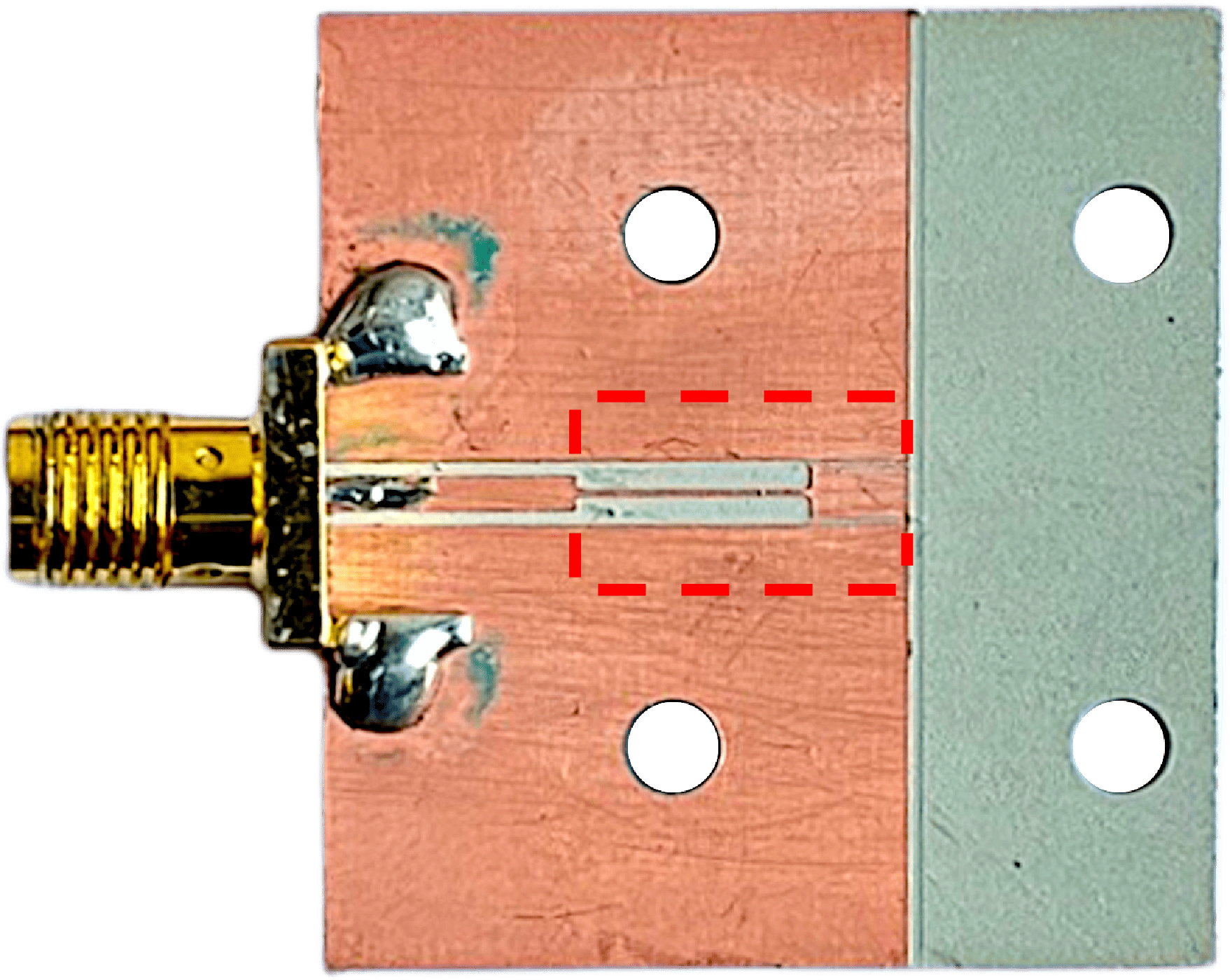

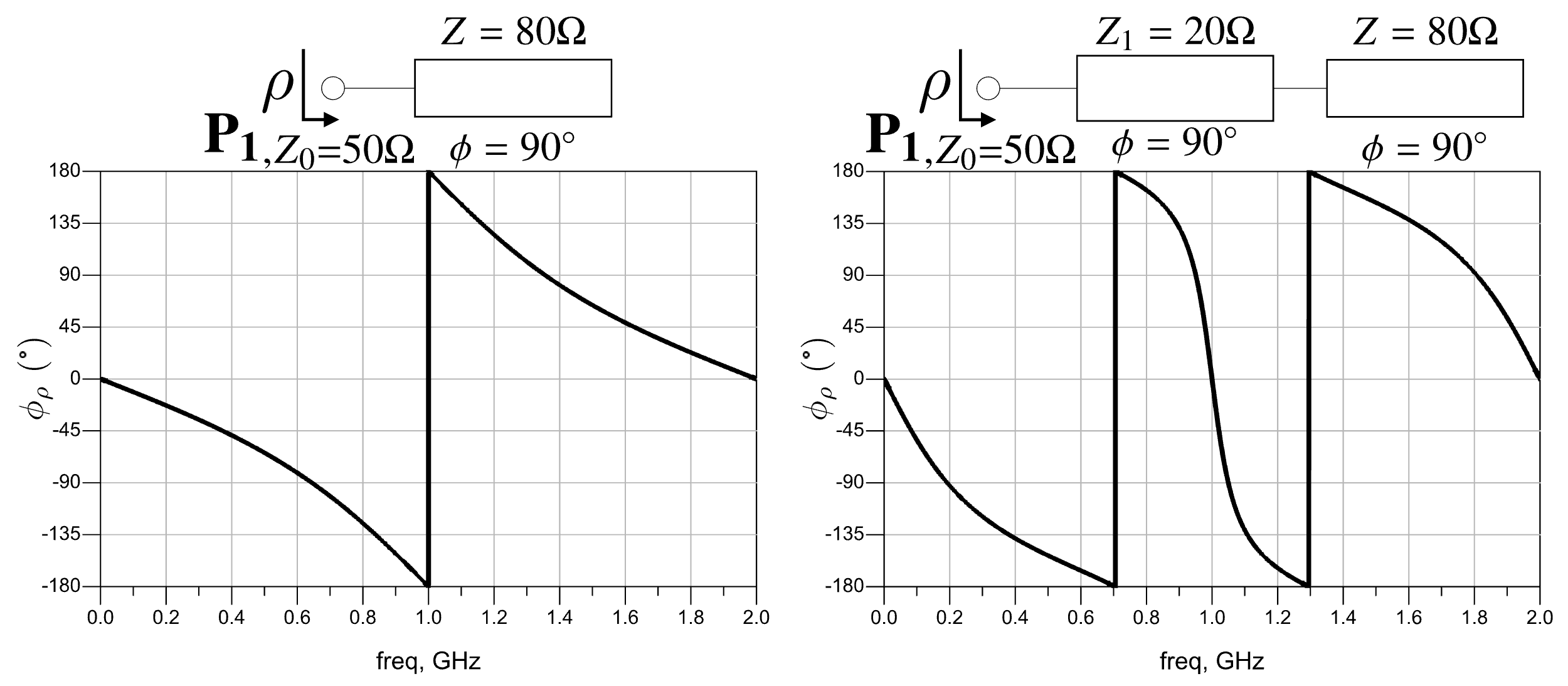

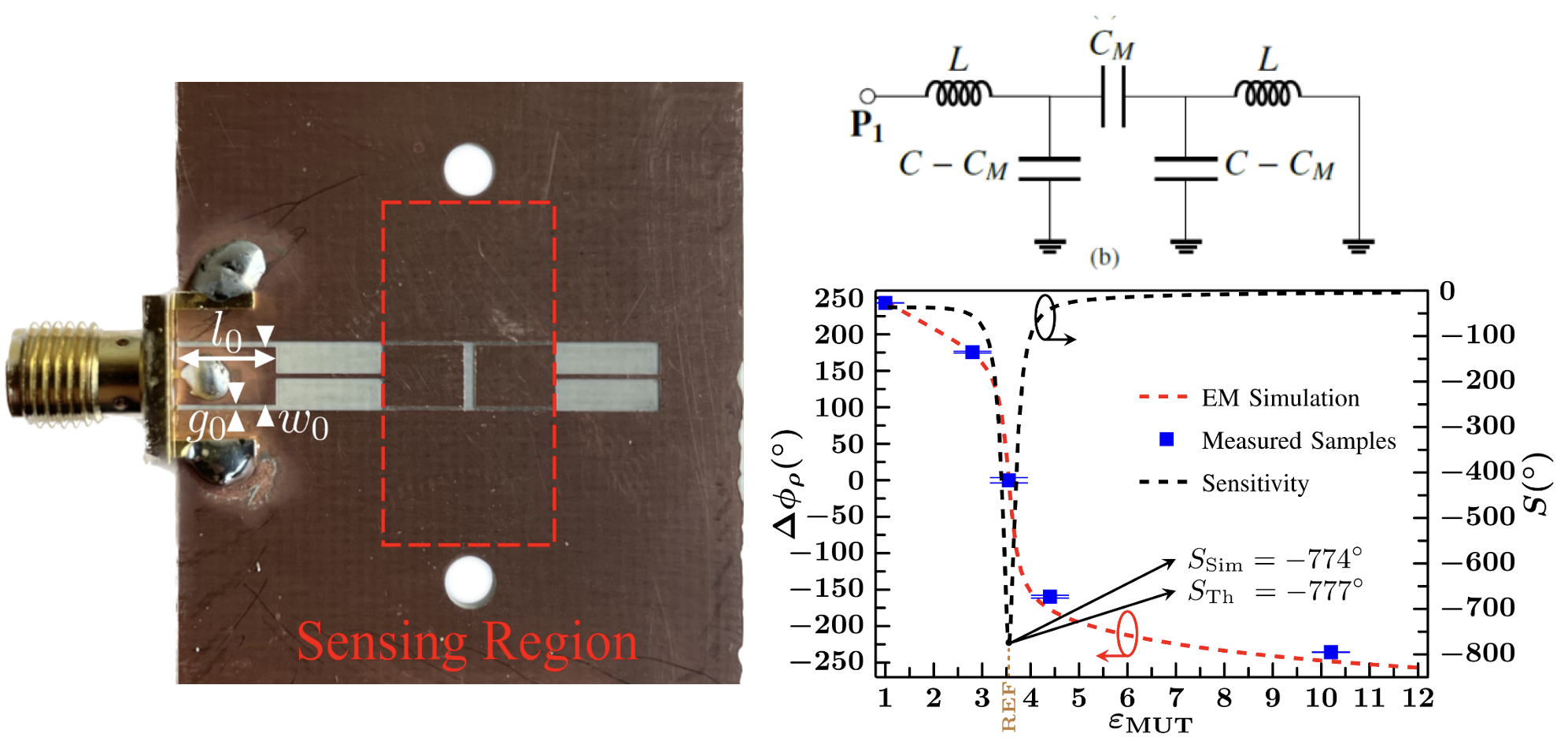

2. Coupled Lines & SIRs

Concept: Two resonators coupled together create two split frequencies.

Reducing coupling $\rightarrow$ Resonances get closer $\rightarrow$ Steeper Phase Slope.

The Coupling Effect

- Strong Coupling: Peaks far apart, shallow slope.

- Weak Coupling: Peaks close, steep slope.

- Limit: If coupling is too weak, recover the single resonator behavior.

Coupled SIRs Results

- Unified Framework: Analyzed all 4 coupling topologies.

- Achievement: Highest senstivity at the time.

- Publications: 5 compendium papers from this technique.

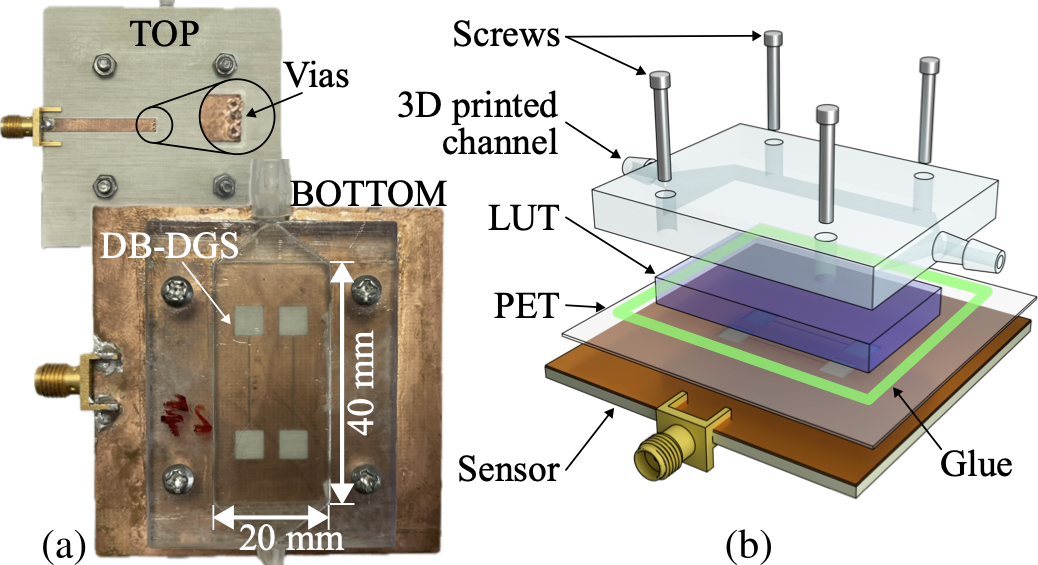

Defect Ground Resonators

Concept: DB-DGS (Dumbbell Defected Ground Structure).

- Separates fluid (ground plane) from circuit (top plane).

- Allows easy integration of fluidic channels.

Publication: [pub:DB-DGS]

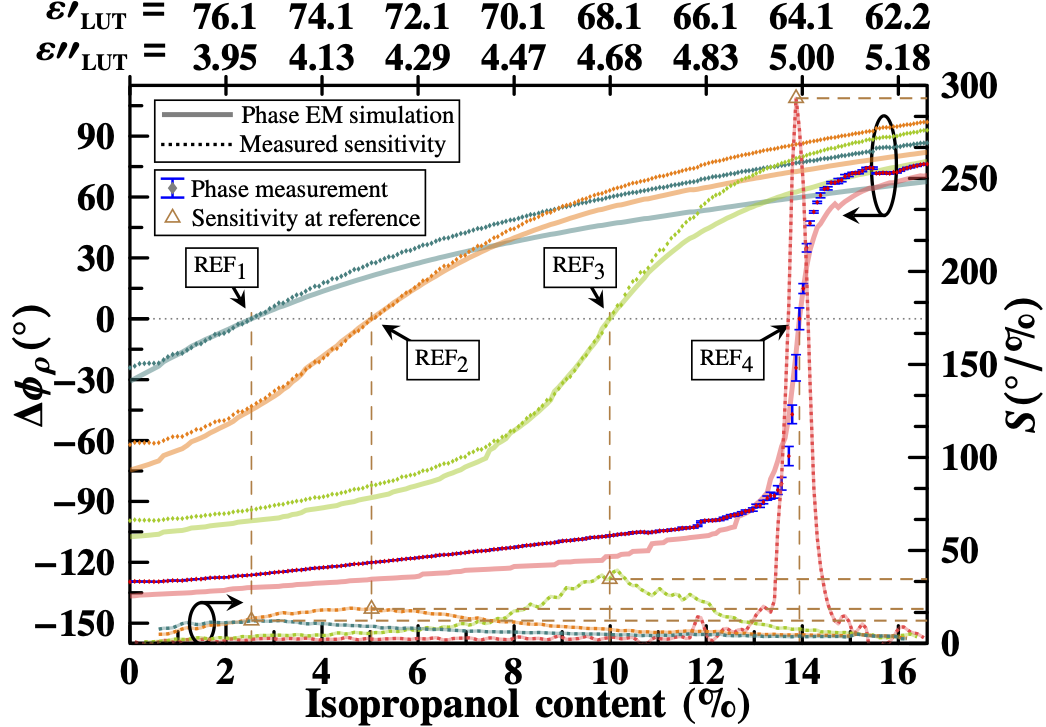

Microfluidics Integration

Challenge: Measuring liquids requires precise handling.

- Liquids allow fine control of permittivity.

- Separate electronics from liquid.

- Need repeatability to validate sensors.

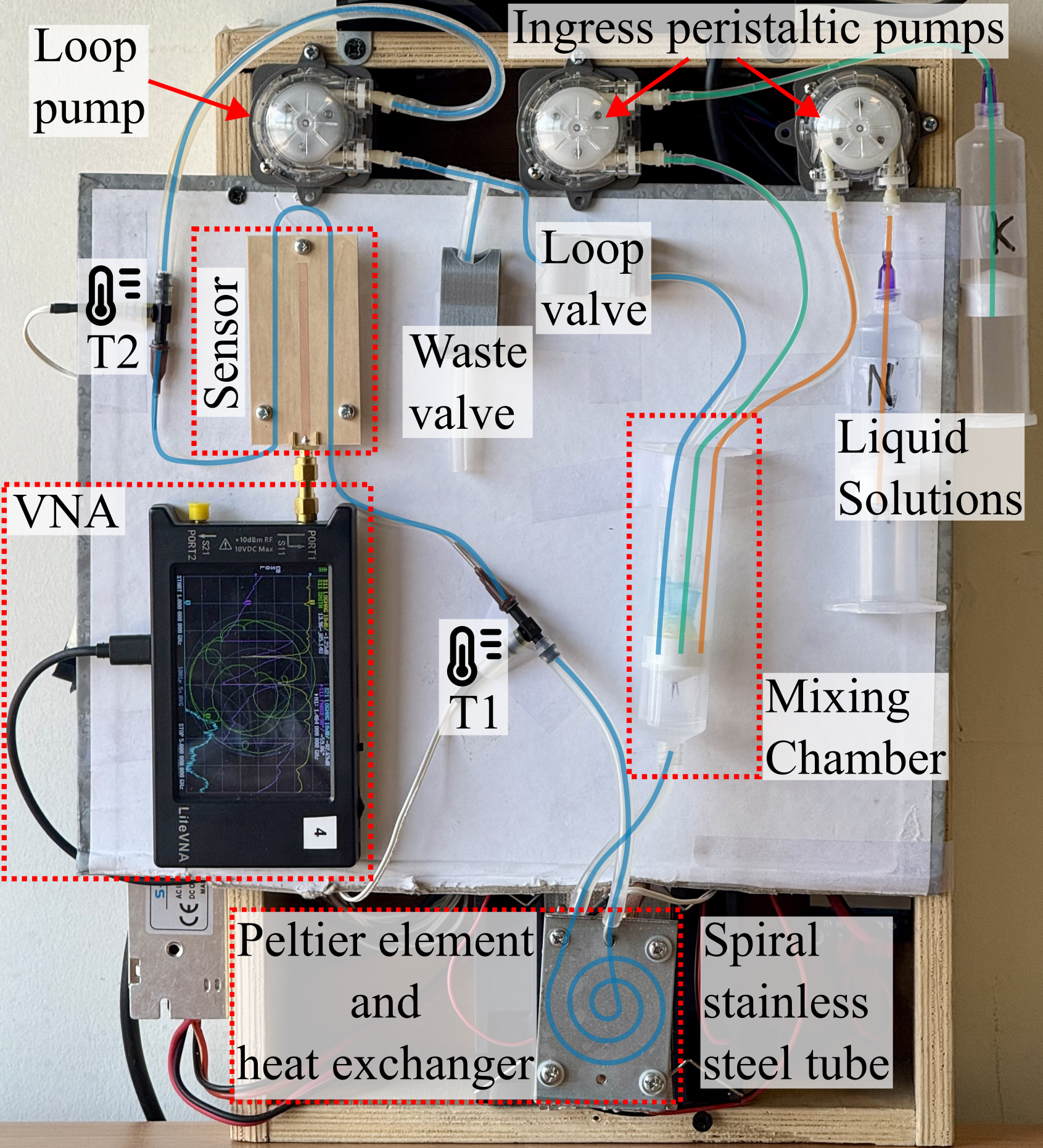

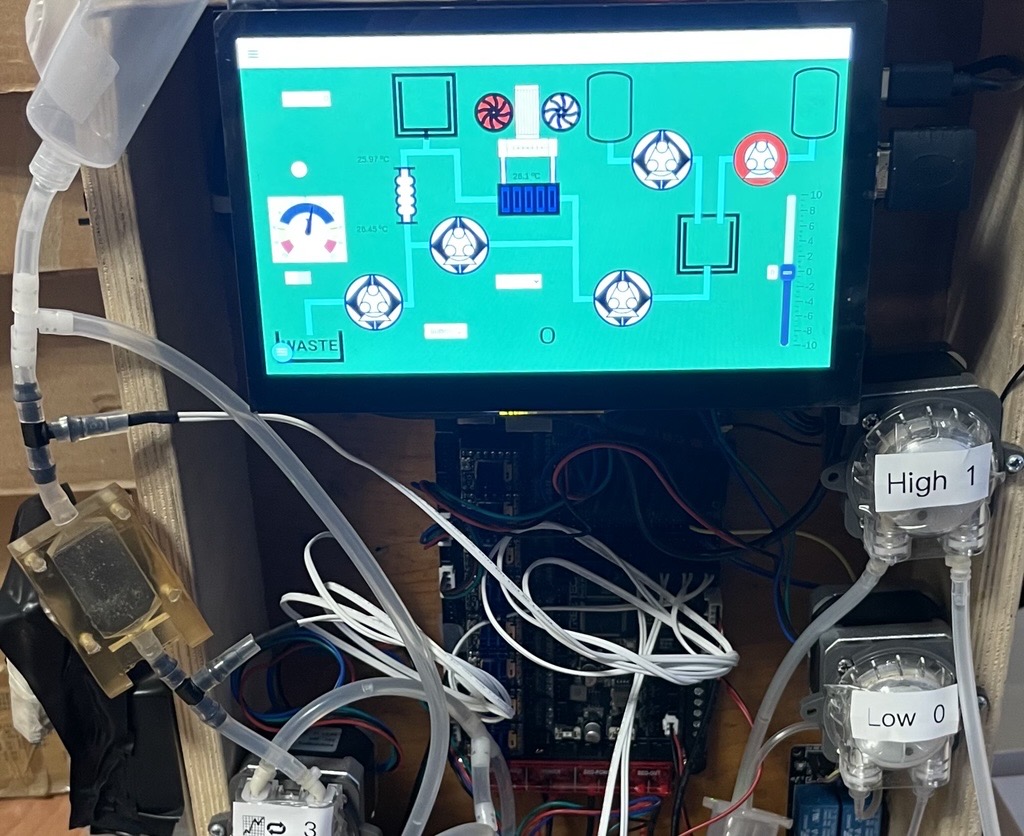

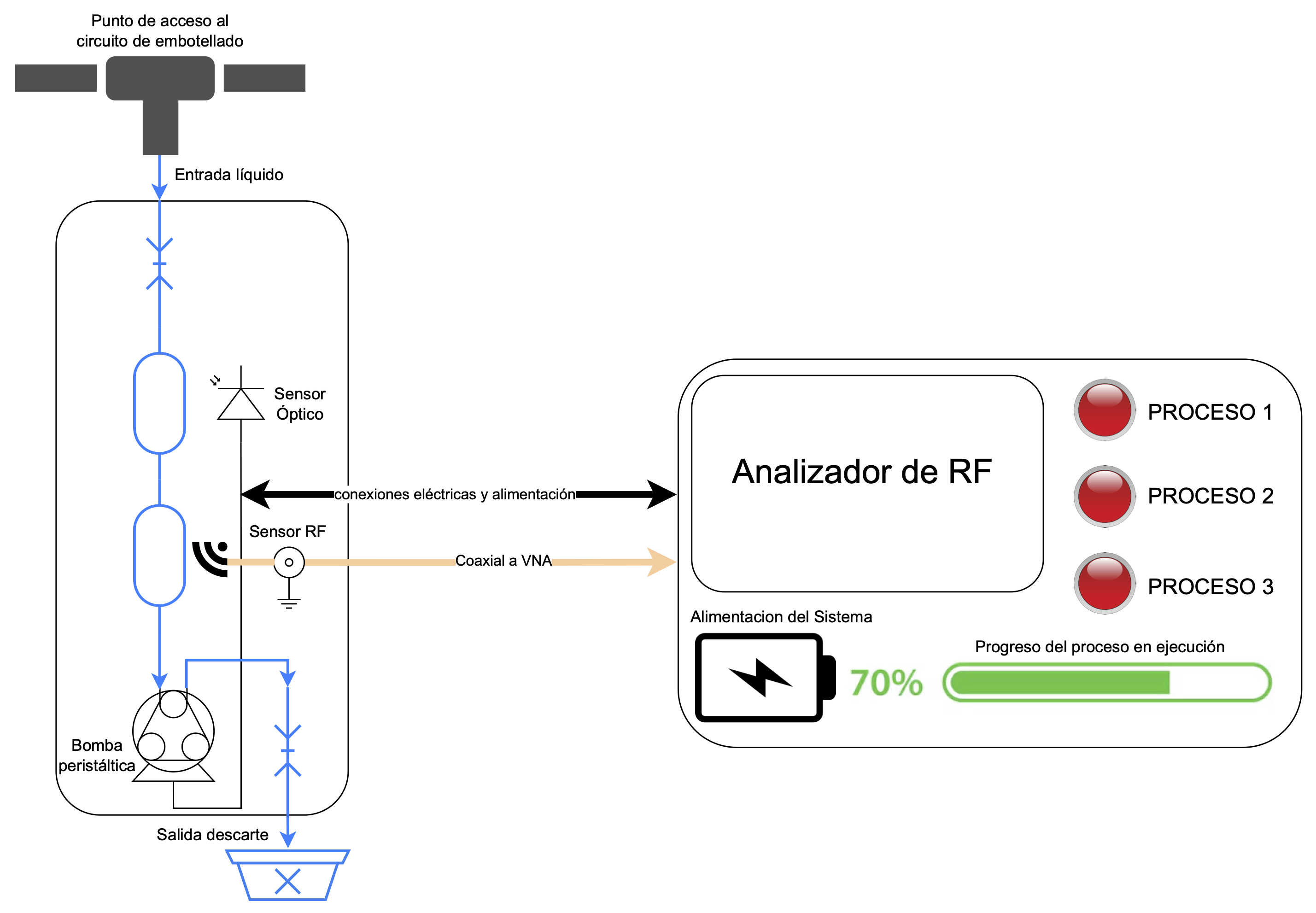

Automated System

- System: Pumps + Temperature Control + VNA.

- Benefit: Automated validation of thousands of samples.

- Key for AI: Enabled generation of large datasets.

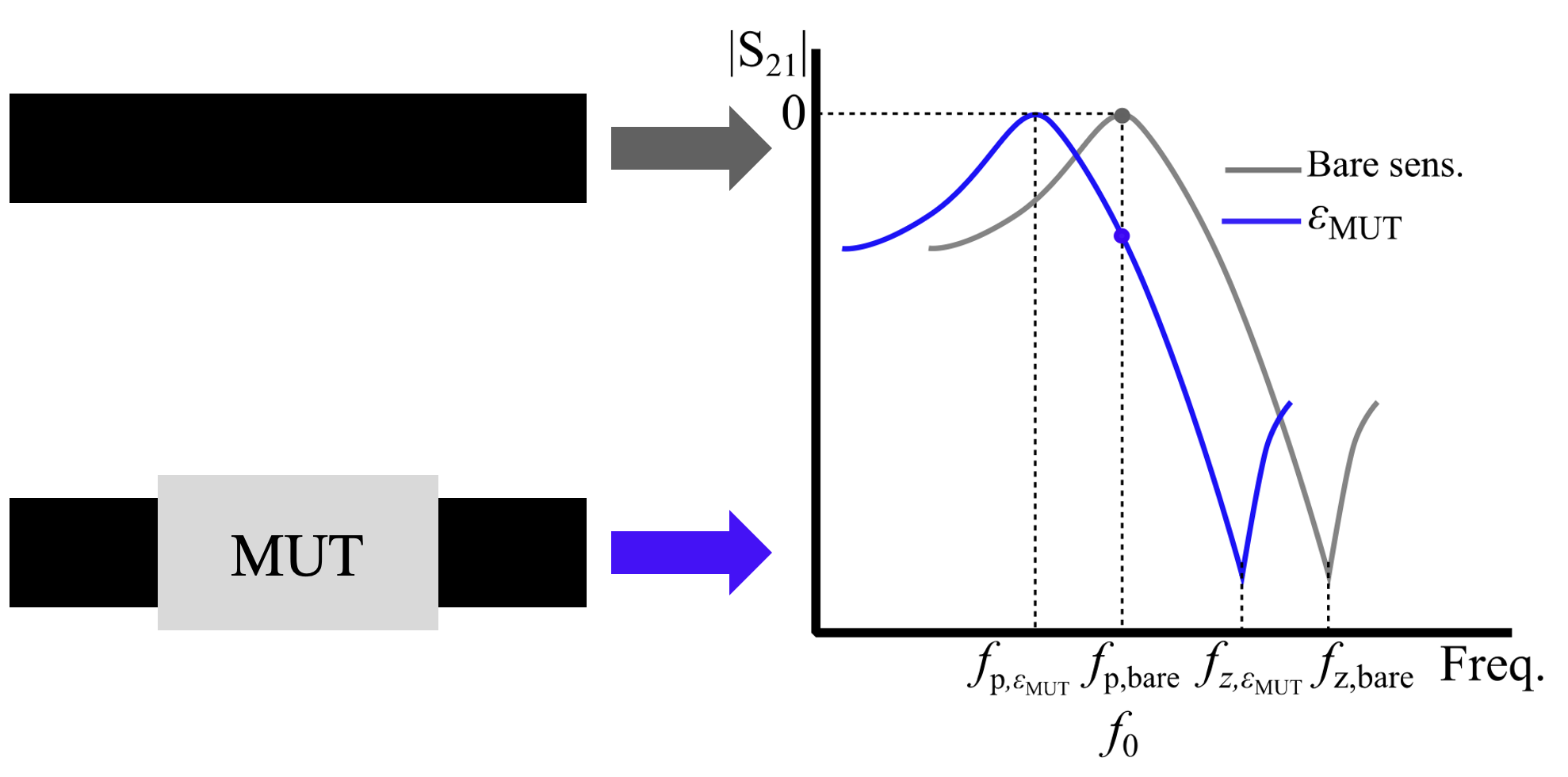

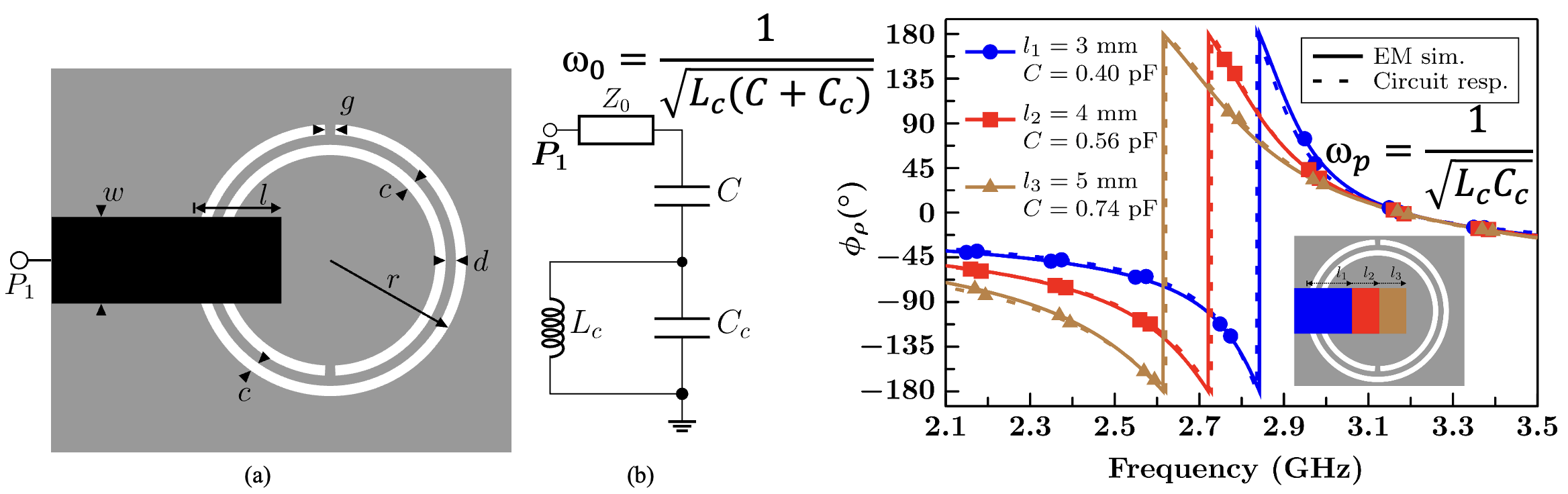

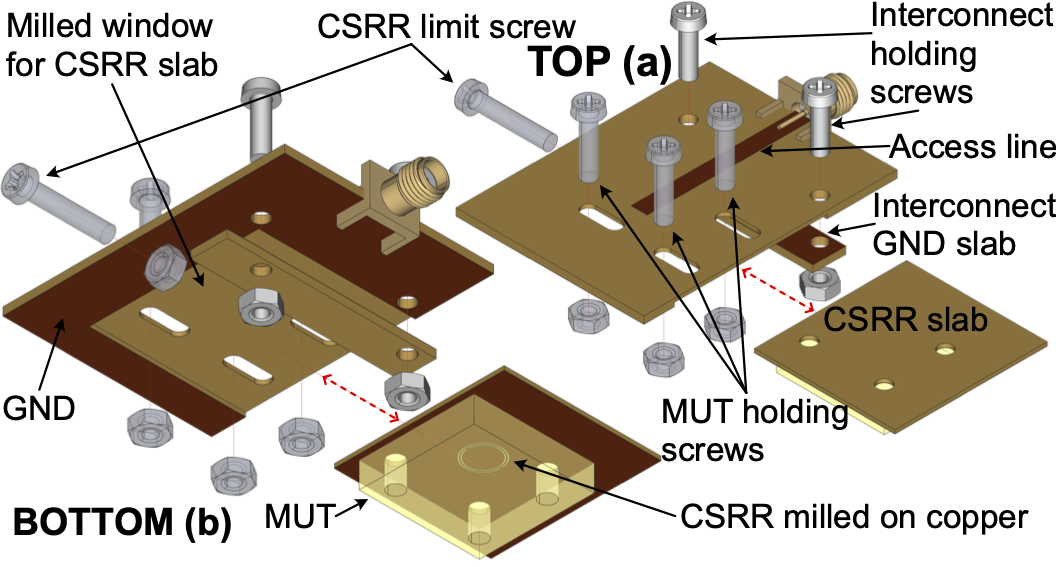

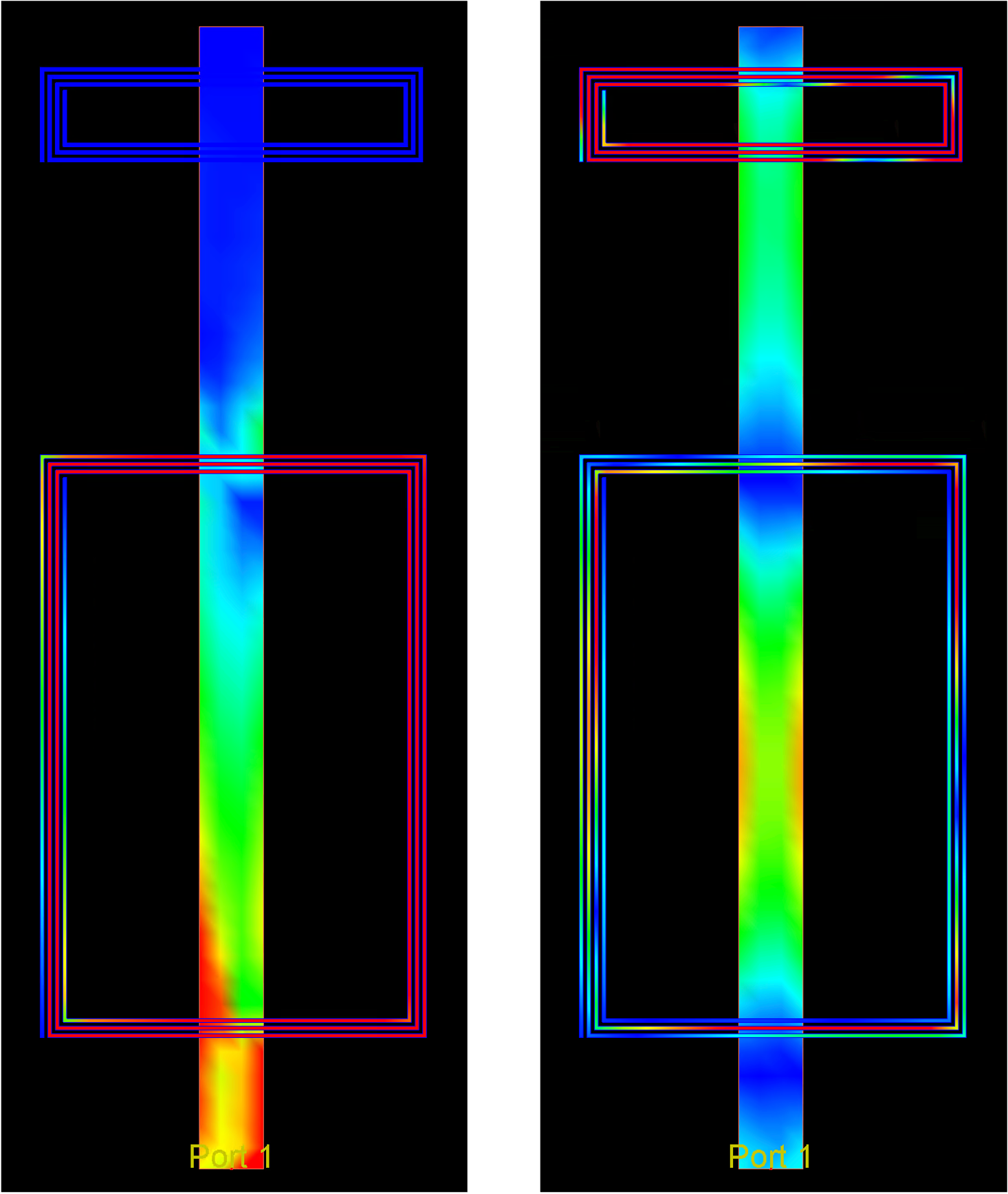

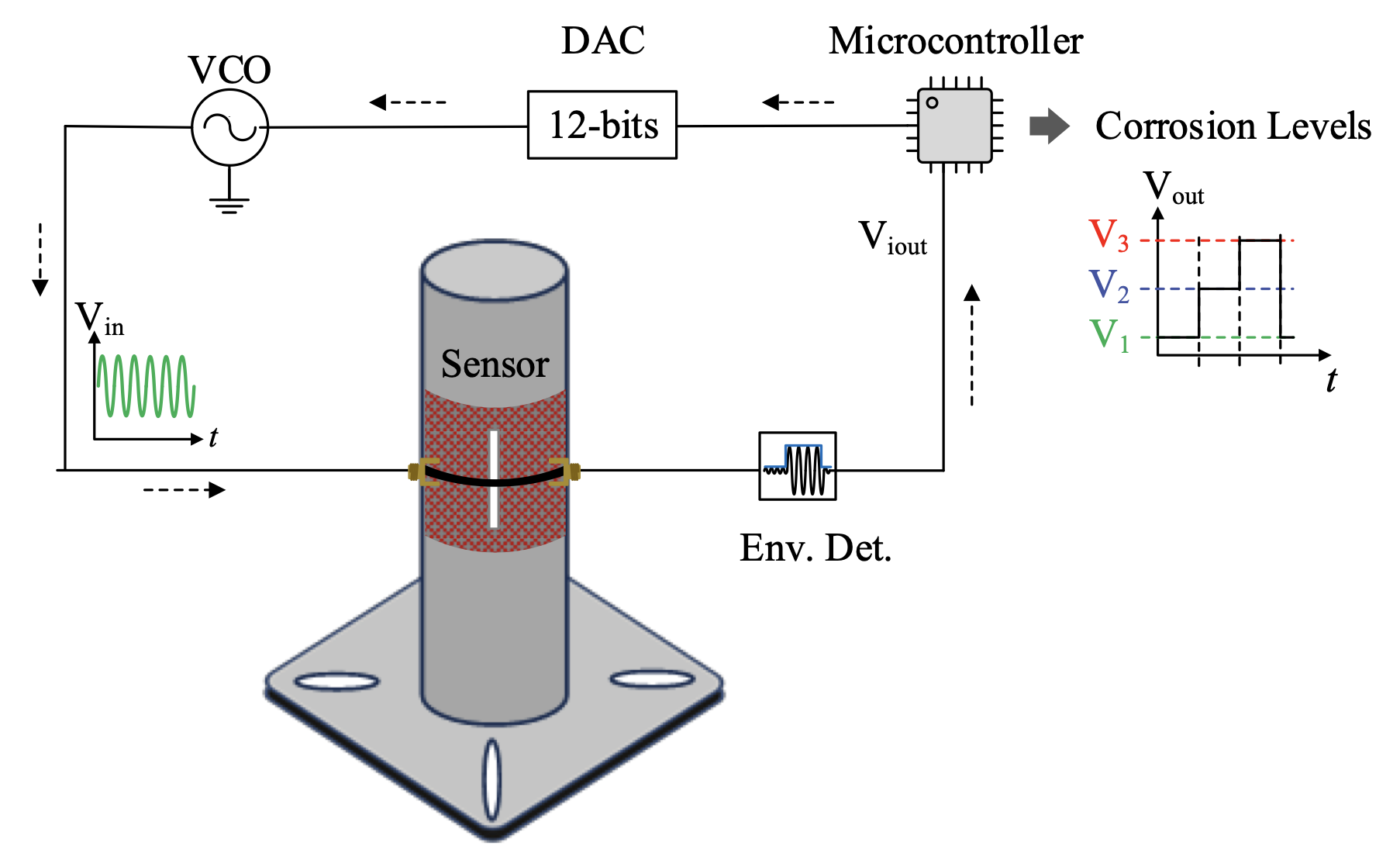

3. Resonance-Antiresonance

Concept: Interaction between a resonance and an antiresonance.

Mechanism: Ground-plane CSRR coupled to a microstrip line, resonance shifts with coupling while antiresonance stays fixed.

Mechanical Tuning

- Innovation: Sensitivity can be tuned by moving the feed line.

- Benefit: Adapt sensitivity to the application without redesigning.

Results

- Sensitivity: > 6350° per unit permittivity.

- Record: Highest sensitivity achieved in the thesis.

- Application: Structural health monitoring (corrosion) or liquid analysis.

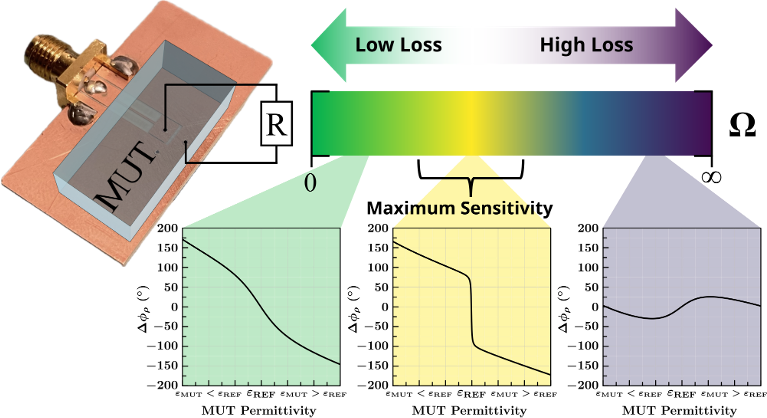

4. Loss Engineering

Paradigm Shift: Instead of minimizing loss, it is a design parameter.

- Concept: Losses can steepen the phase slope near resonance.

- Result: Enhanced sensitivity without changing the geometry.

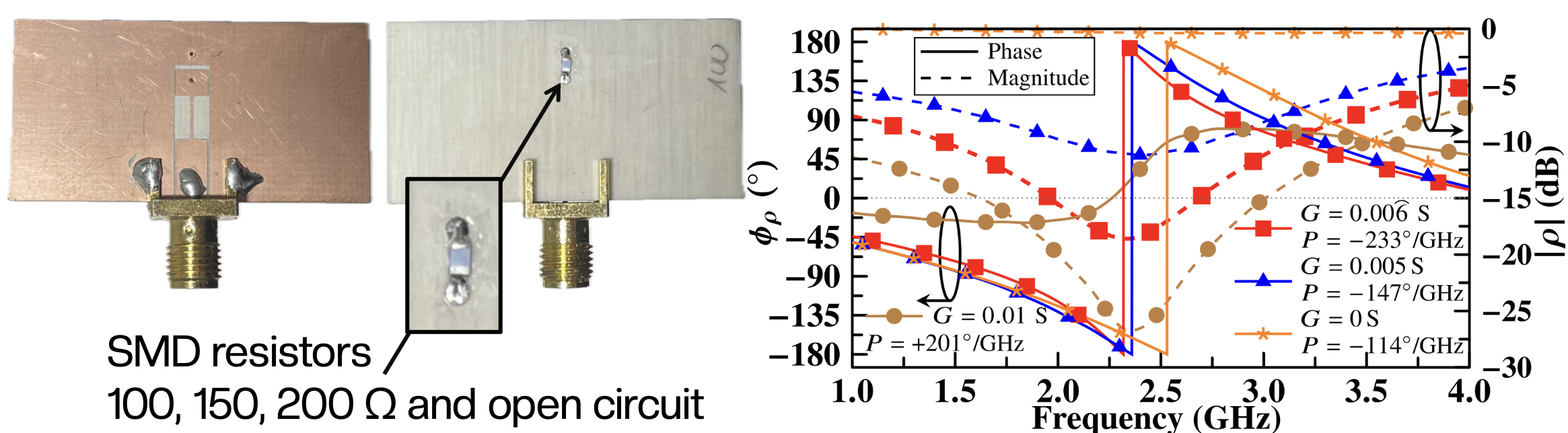

Passive Implementation

Method: Adding resistive loading to coupled lines.

- Mechanism: Resistors control the coupling quality factor.

- Outcome: Steeper phase response in the sensing region.

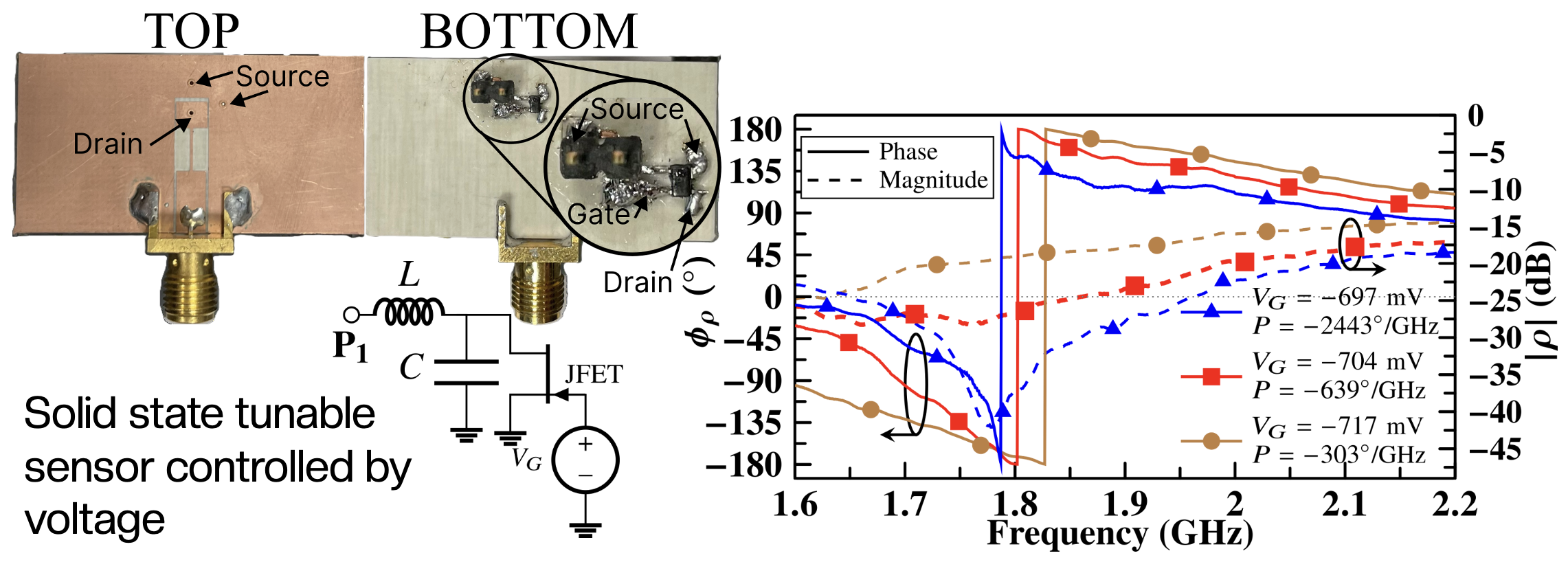

Active Tunable Sensitivity

Method: Using a JFET as a voltage-controlled resistor.

- Innovation: Real-time control of sensitivity.

- Application: Adapt the sensor to different materials dynamically.

AI-Driven Sensing

The Selectivity Challenge

High Sensitivity $\neq$ Identification

We can detect that something has changed, but not what has changed.

Arbitrary High Sensitivity Accomplished

Explore new applications where selectivity is important a part from sensitivity.

The Solution: Spectrometry + AI

- Spectrometry: Materials behave differently at different frequencies.

- Broadband Measurement: Capture the "fingerprint" of the material.

- Why AI? Analytical models are too complex for multi-variable inverse problems.

- Traditional design process: Physical Model $\rightarrow$ Analytical Inversion $\rightarrow$ Parameter

- New design process: Data $\rightarrow$ Machine Learning Model $\rightarrow$ Prediction

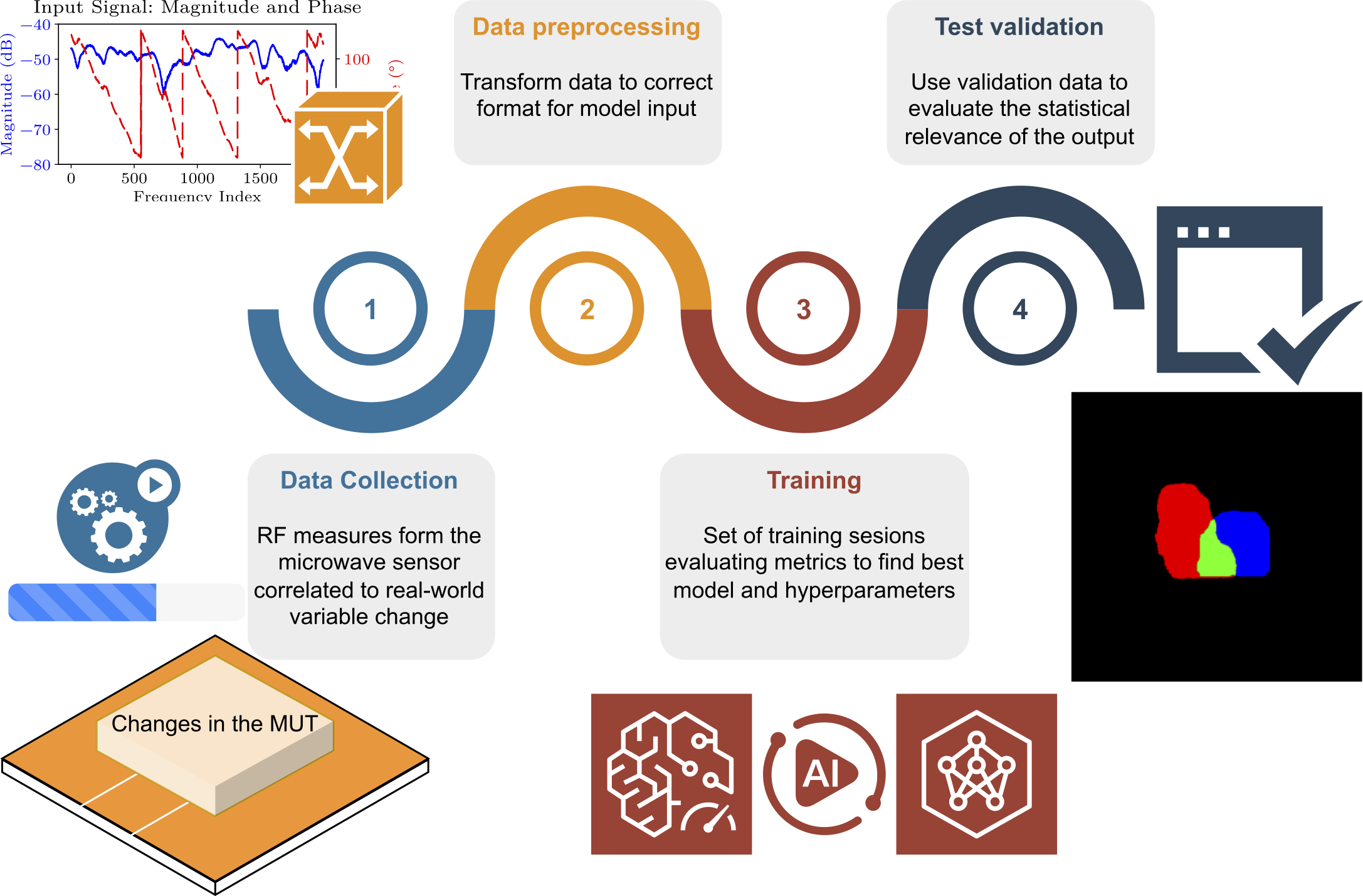

The Pipeline

- Design Sensor: For contrast, not just sensitivity.

- Generate Data: Automated measurements / Simulation.

- Train Model: Learn the mapping (Spectrum $\rightarrow$ Variable).

- Inference: Real-time prediction.

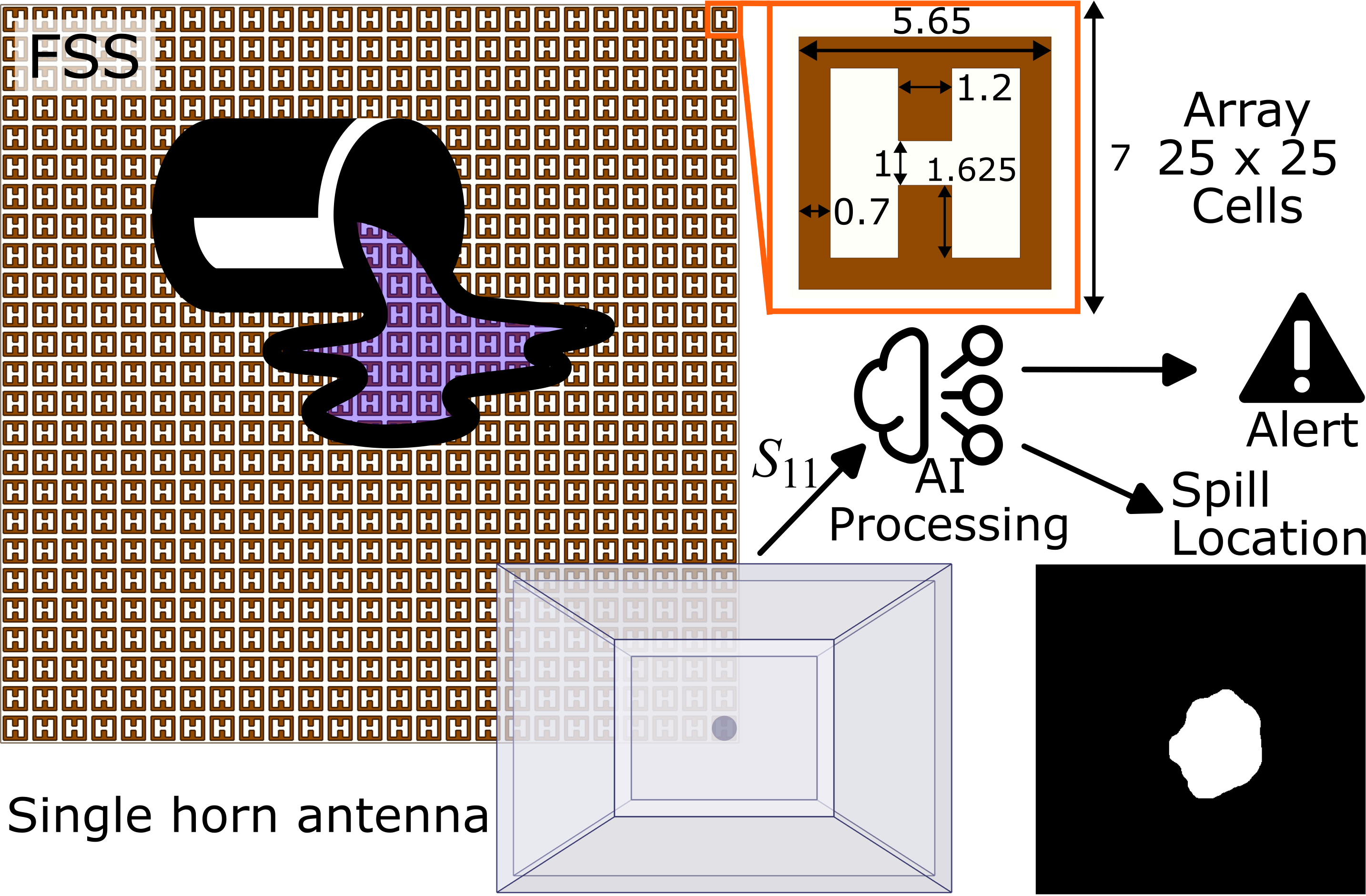

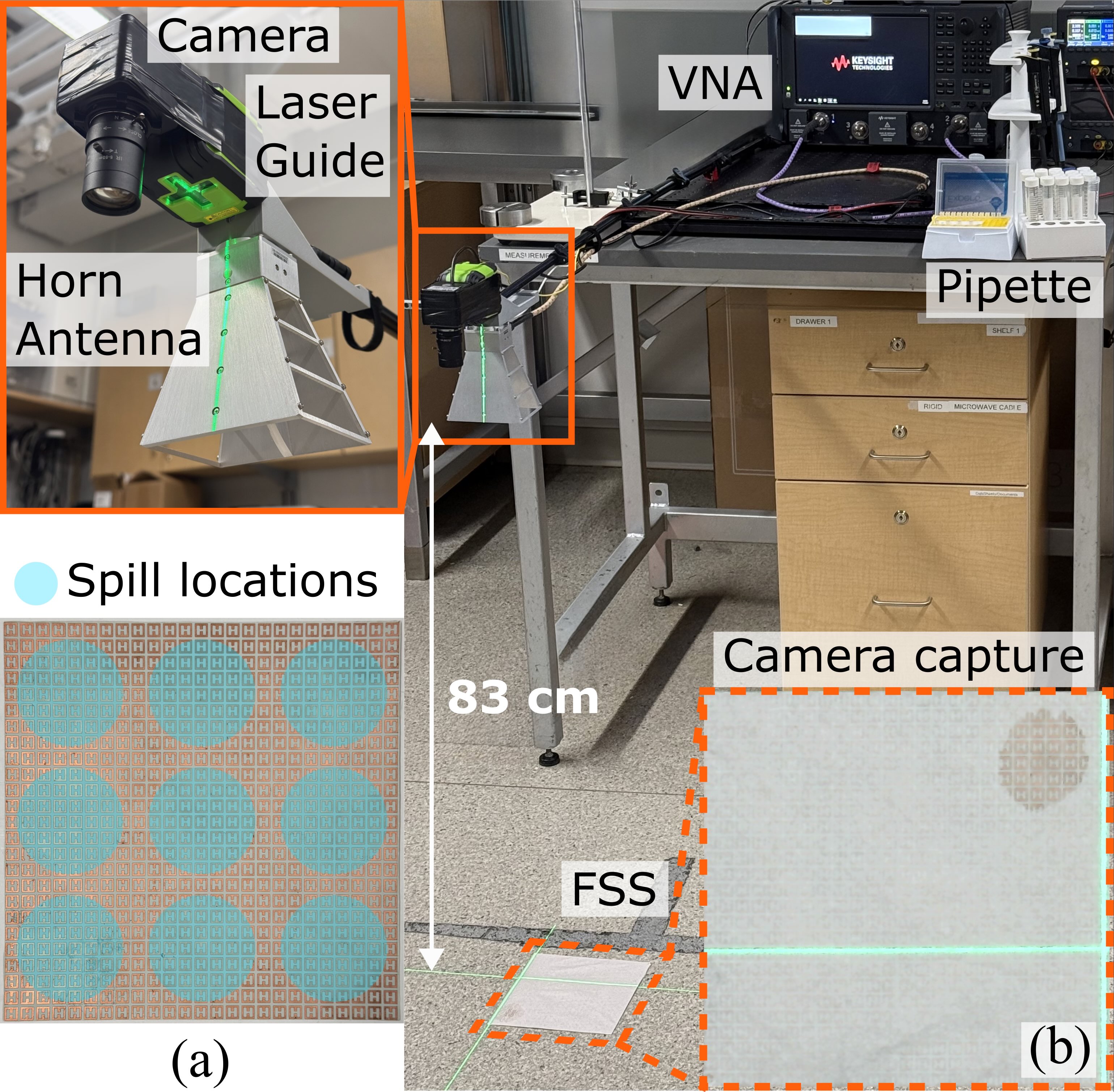

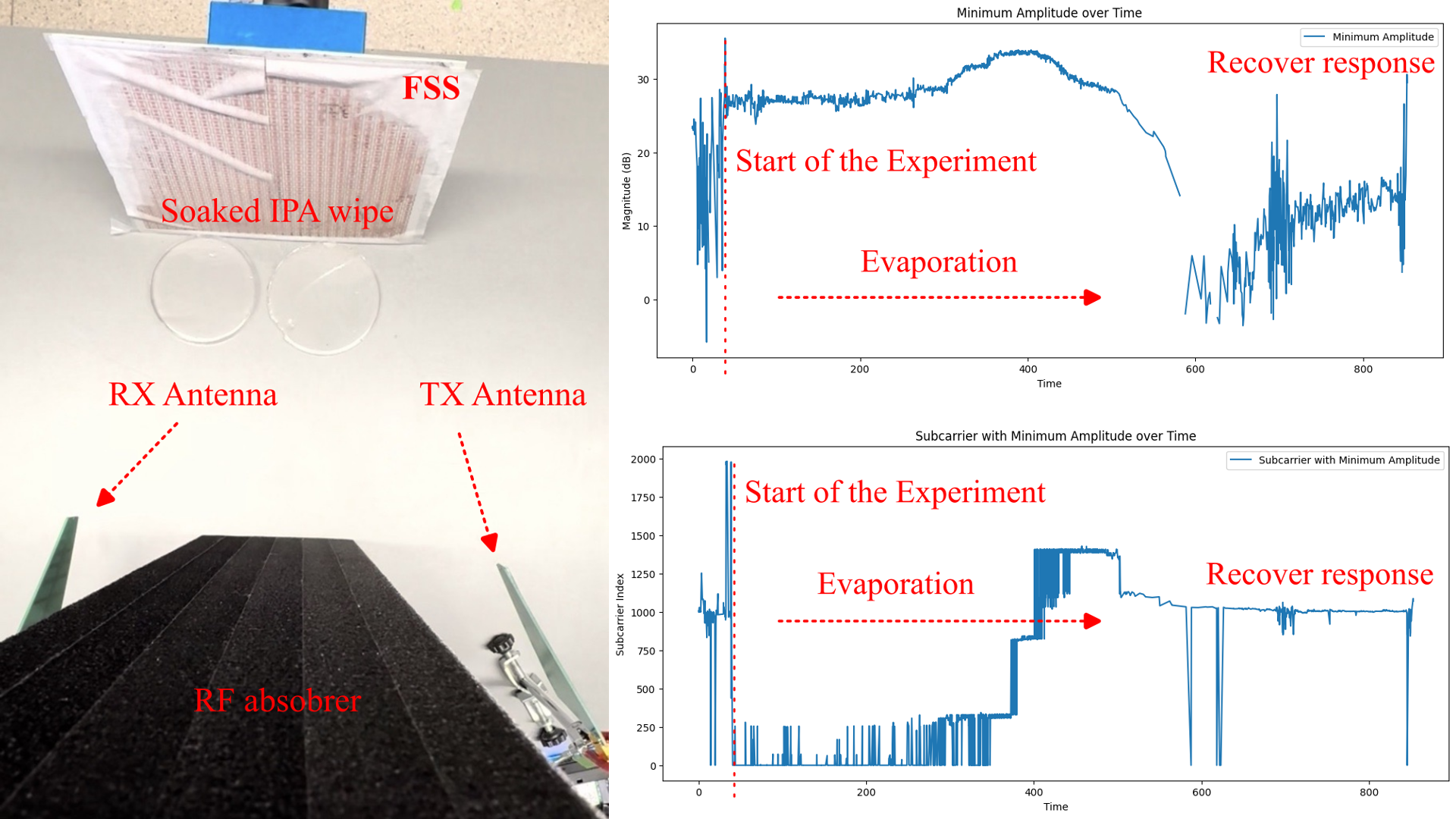

Case 1: Remote Sensing with FSS

Scenario: Detecting liquid spills remotely.

Sensor: Frequency Selective Surface (FSS) tag.

Challenge: Signal depends on liquid type AND position.

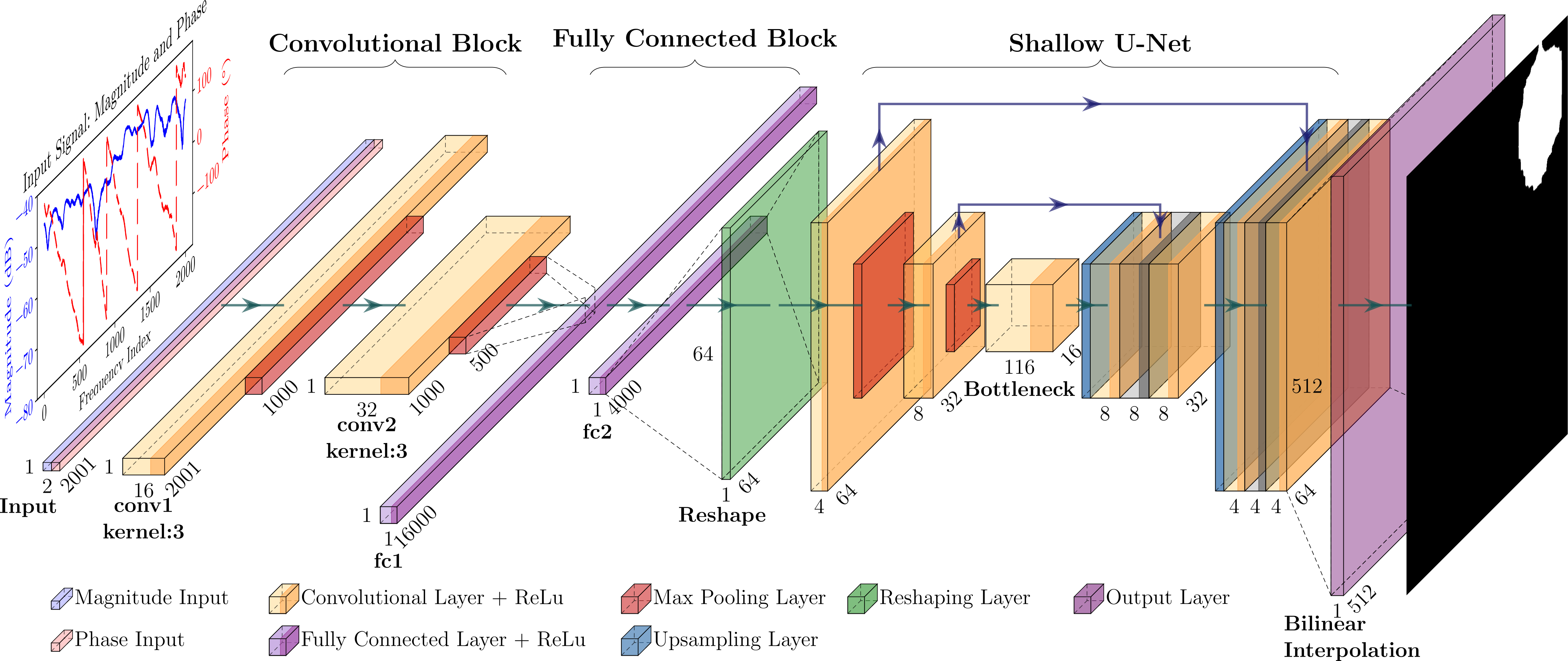

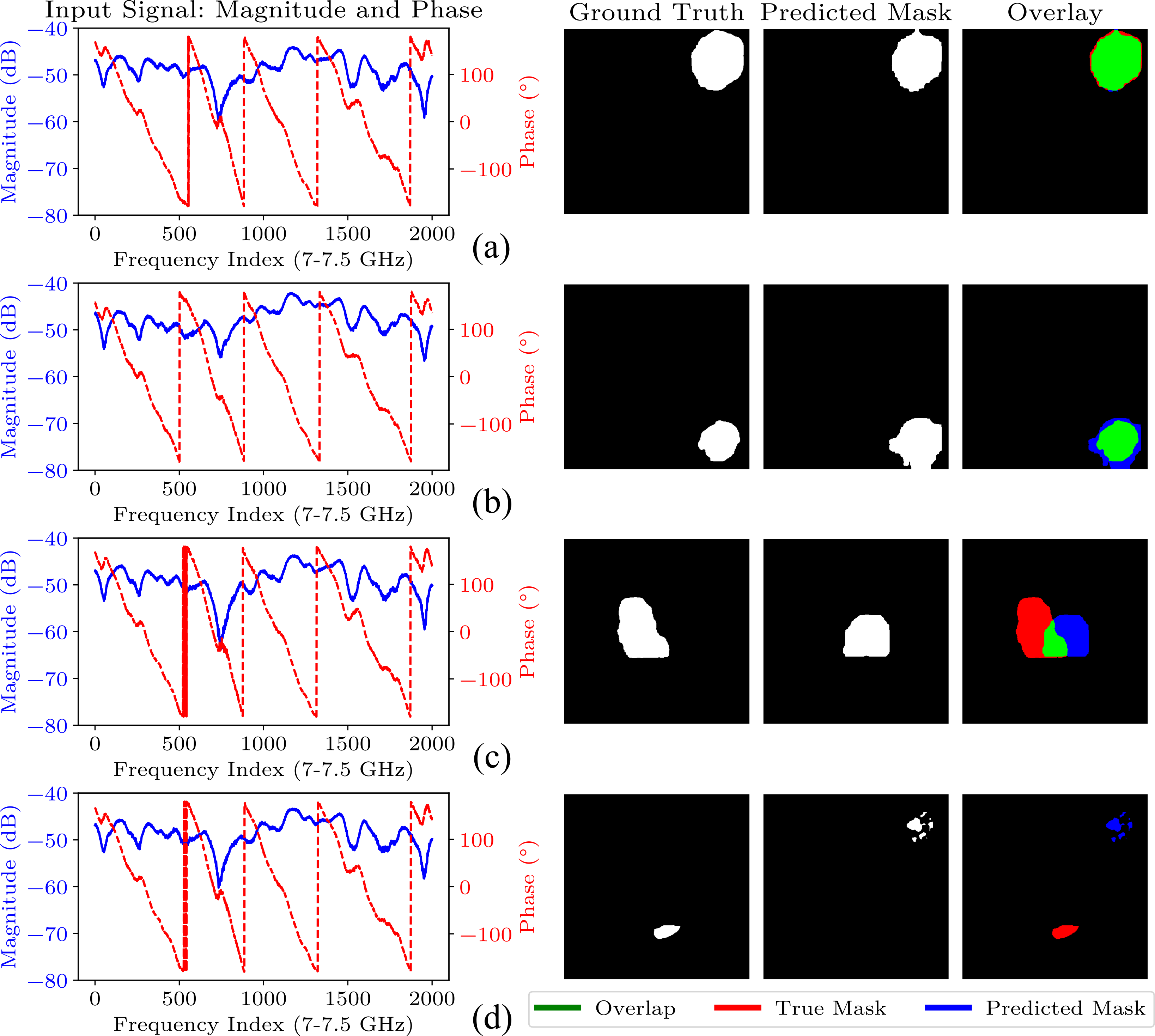

FSS Solution: CNN + U-Net

- Input: Single radar echo (1D spectrum).

- CNN Model: Signal feature extraction.

- MLP Model: Latent space mapping.

- U-Net Model: Spatial Mask reconstruction.

FSS Results

Output: Liquid Type + Spatial Image of the Spill.

We reconstruct an image from a spectral microwave measurement!

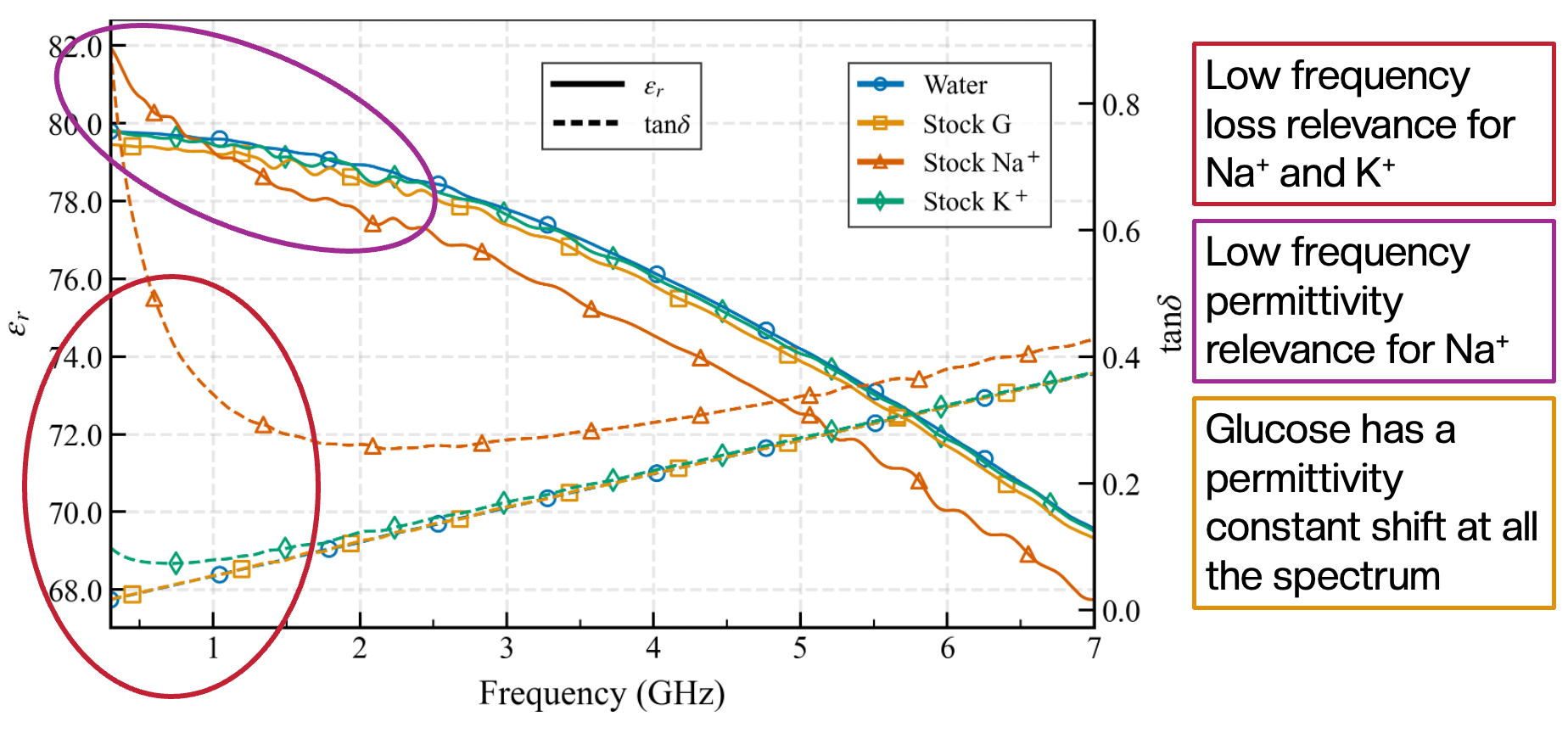

Case 2: Multi-Analyte Sensing

Goal: Measure Glucose, Sodium, and Potassium simultaneously.

Context: Blood analysis.

Challenge: Selectivity. Distinguishing ions from glucose.

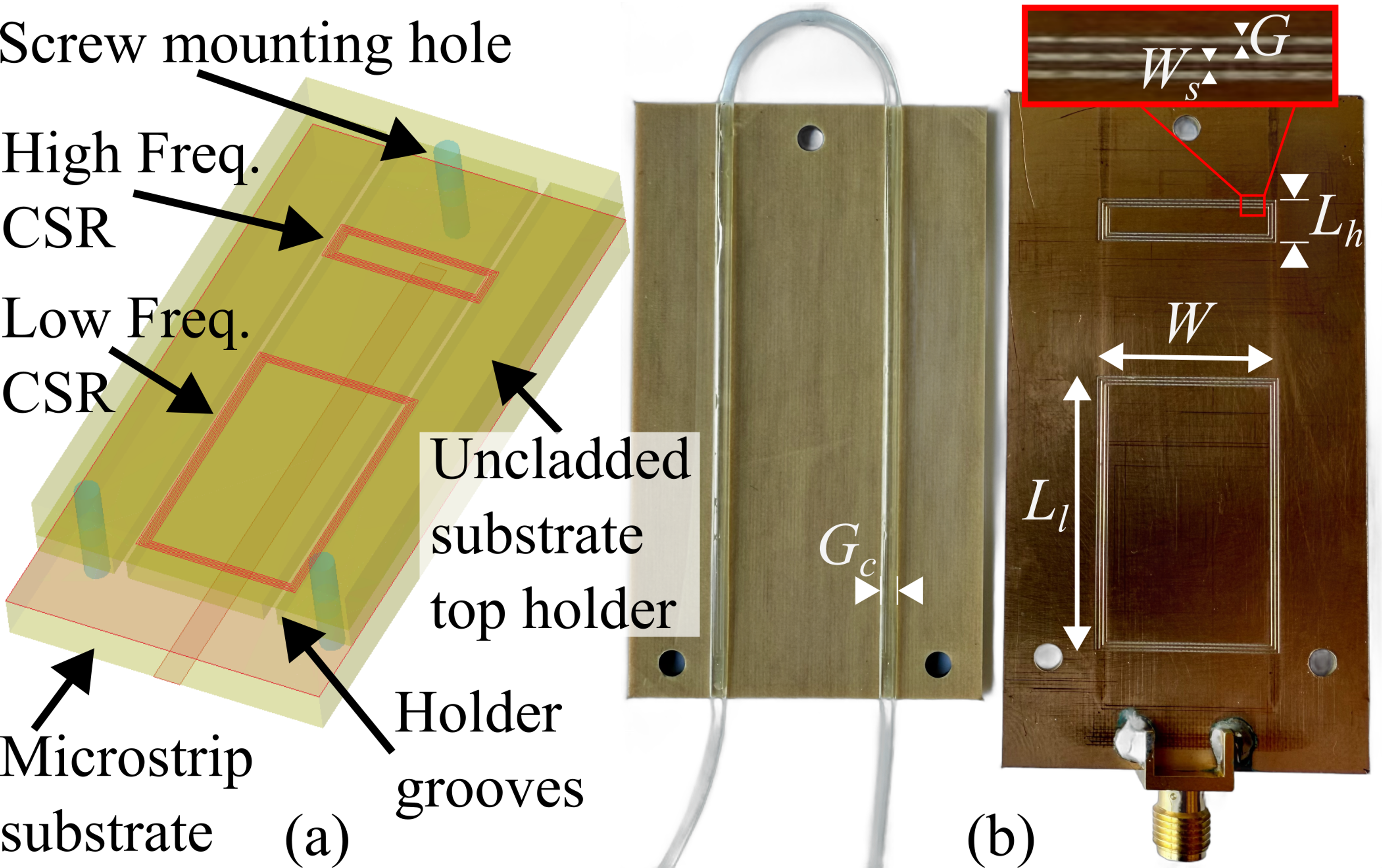

Multi-Analyte Sensor Design

- Sensor: Multi-resonant spiral sensor.

- Feature: Broadband response (100 MHz - 6 GHz).

- Design: Optimized to have features sensitive to different components.

Data Generation

- Automated System: Used the microfluidics system from Objective 2.

- Dataset: Hundreds of mixtures with a set of concentrations.

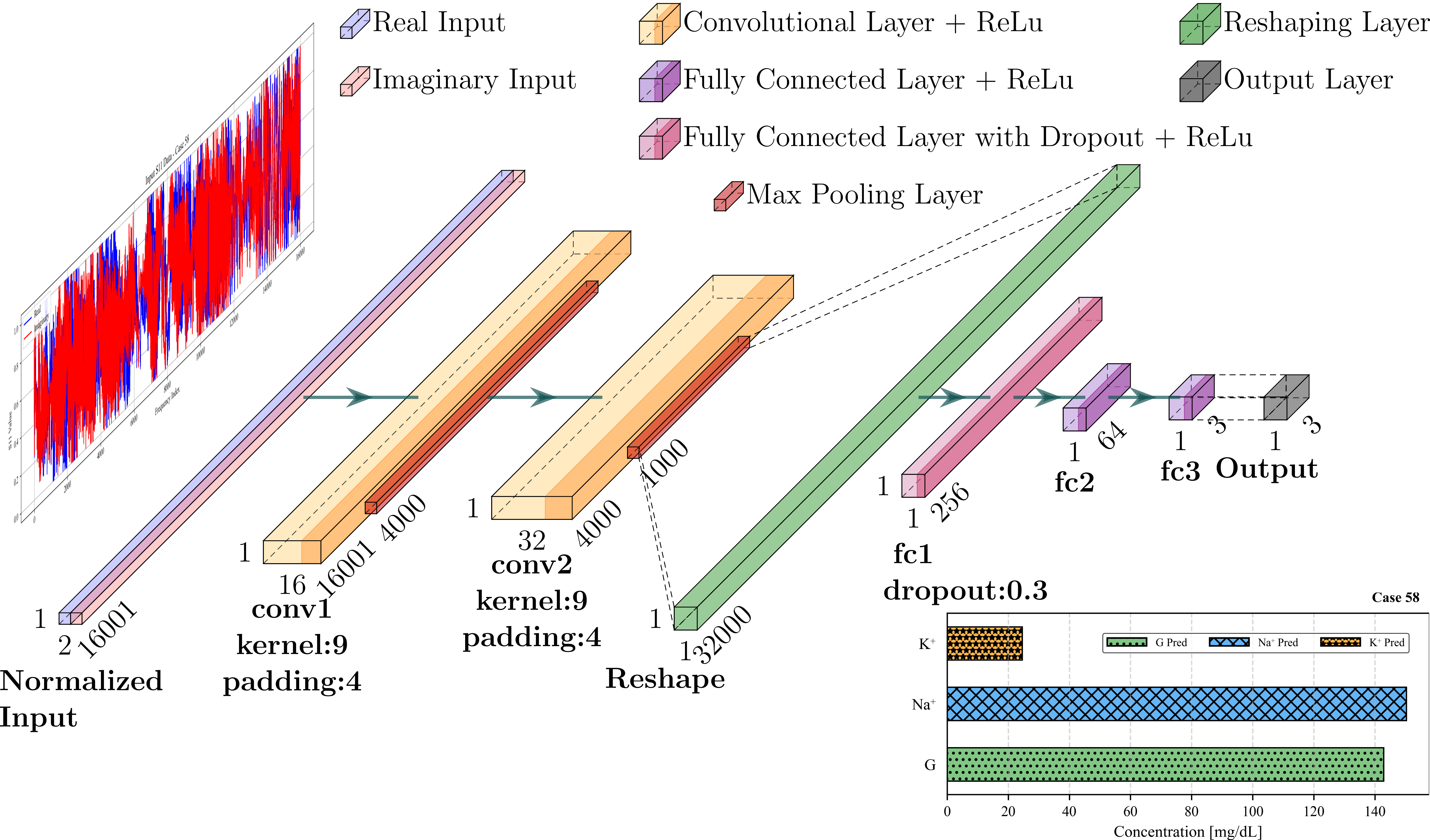

- Model: CNN + Regression Neural Network.

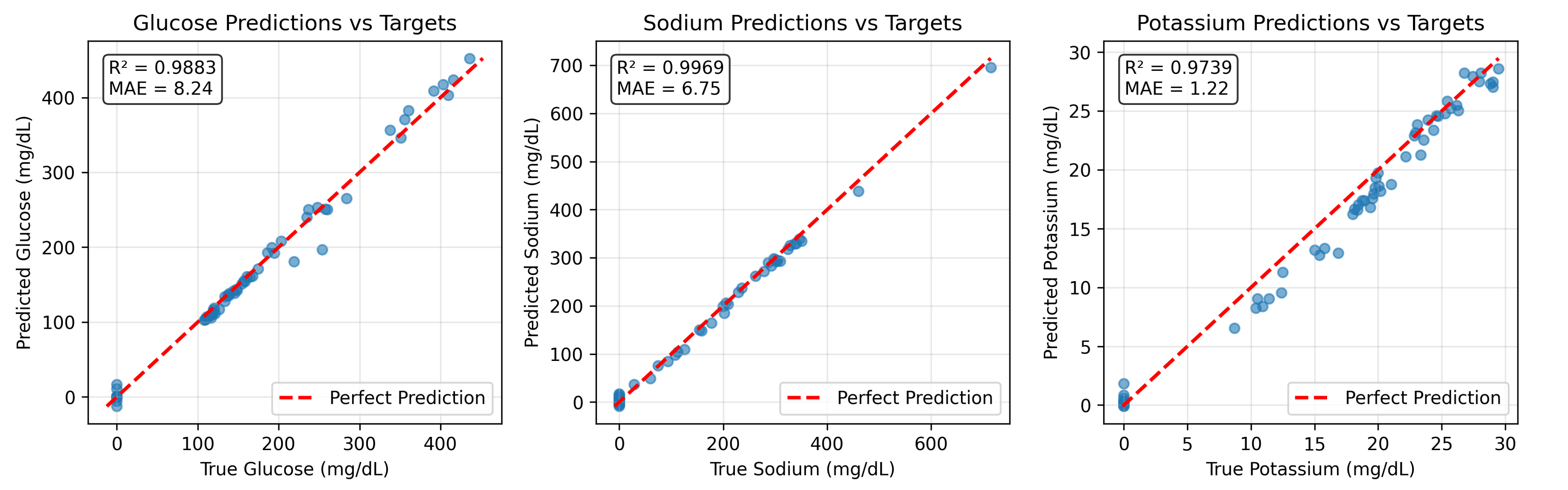

Multi-Analyte Sensor Results

- Model: Regression Neural Network.

- Outcome: Accurate concentrations for all 3 solutes.

- Error: Low enough for clinical screening potential.

Applications & Discussion

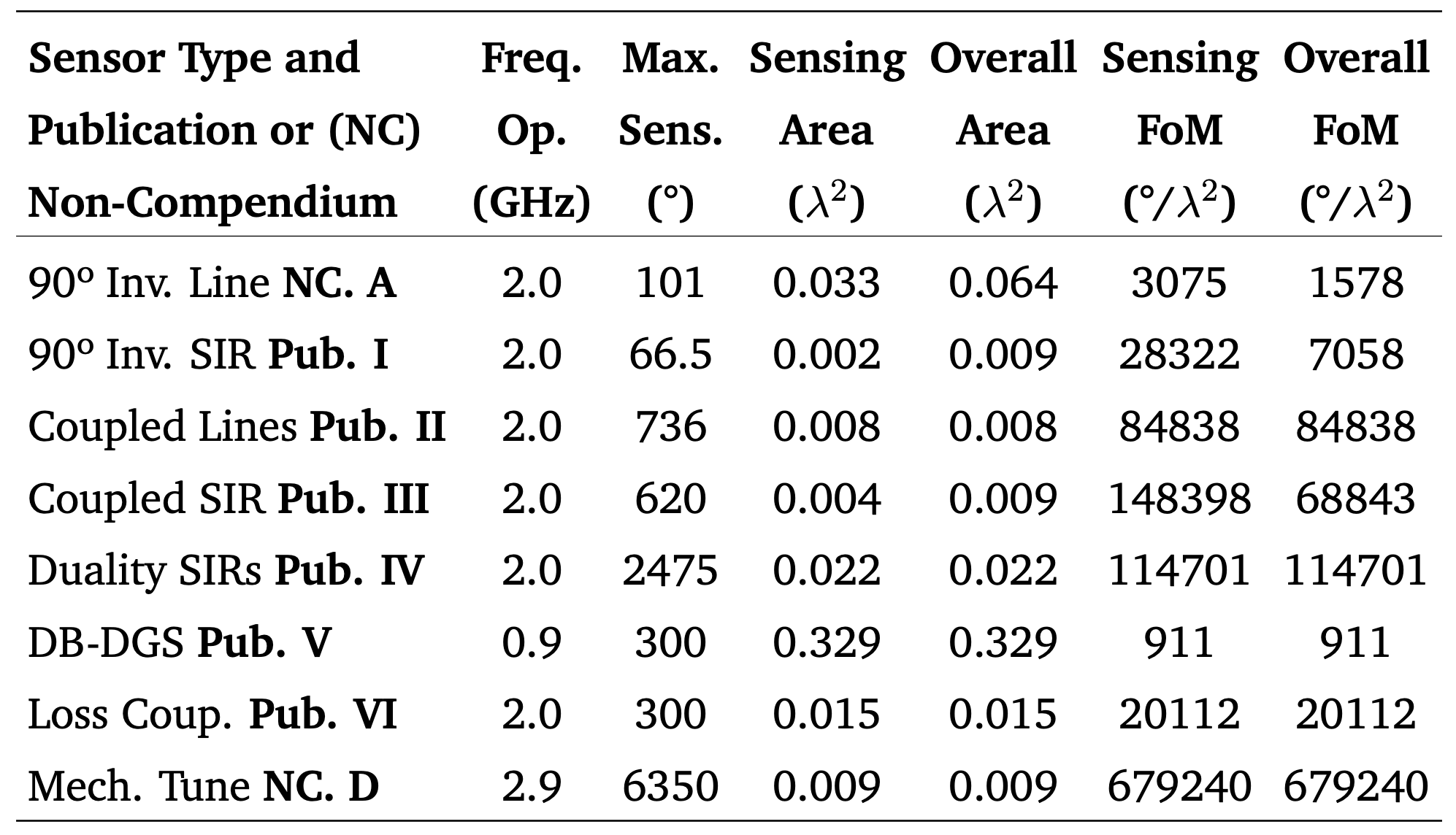

Evolution of Performance

Figure of Merit (FoM): Sensitivity / Size.

Consistent trend: Higher sensitivity in smaller footprints.

Loss Engineering and Tunability

Paradigm Shift: Loss is usually bad.

Our Finding: Controlled loss can sharpen the phase response.

- Used resistors/JFETs to tune sensitivity.

- Loss as a Design Parameter.

- Enables dynamic adjustment of sensitivity for specific application requirements.

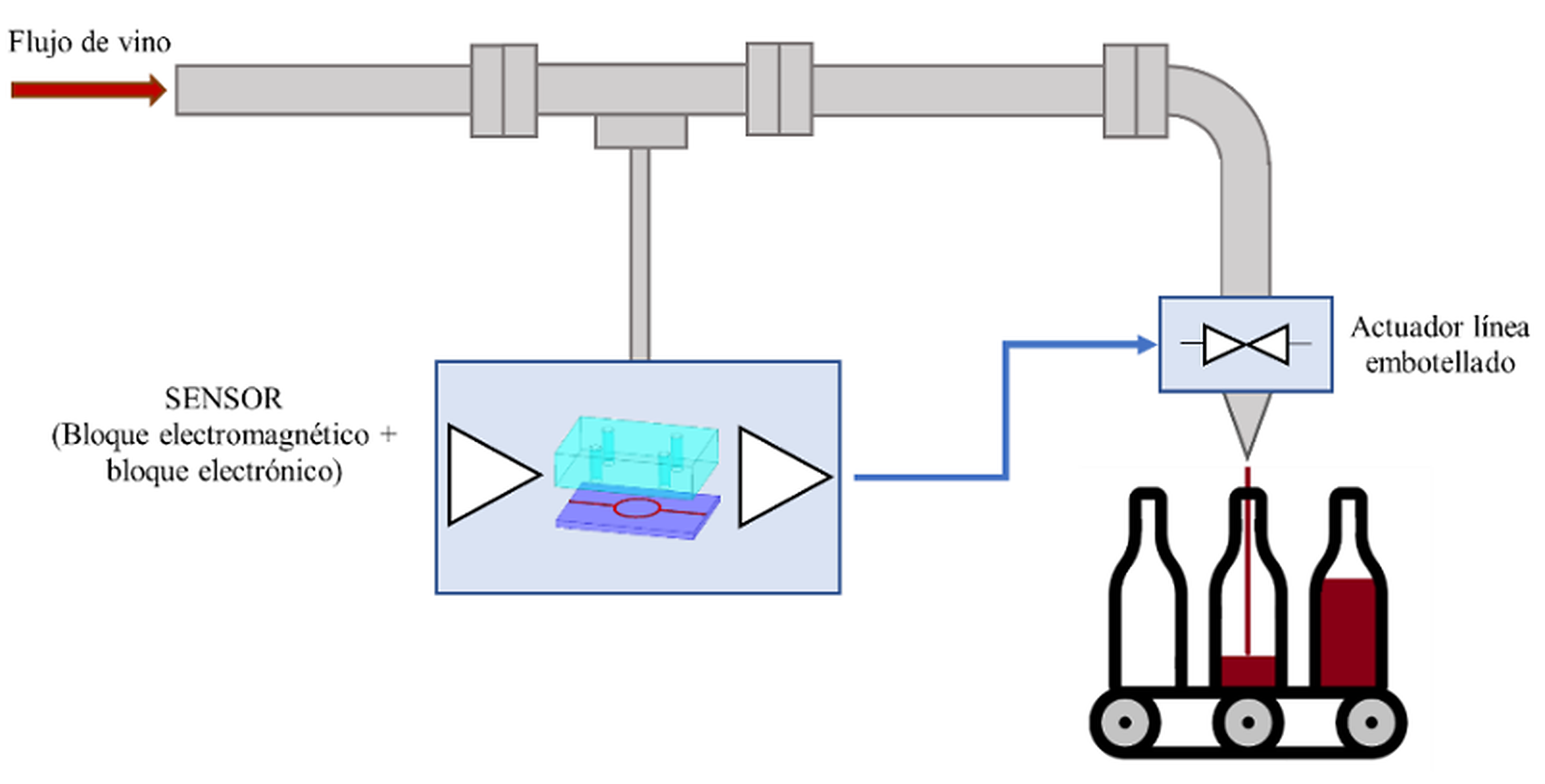

Application: Agrifood

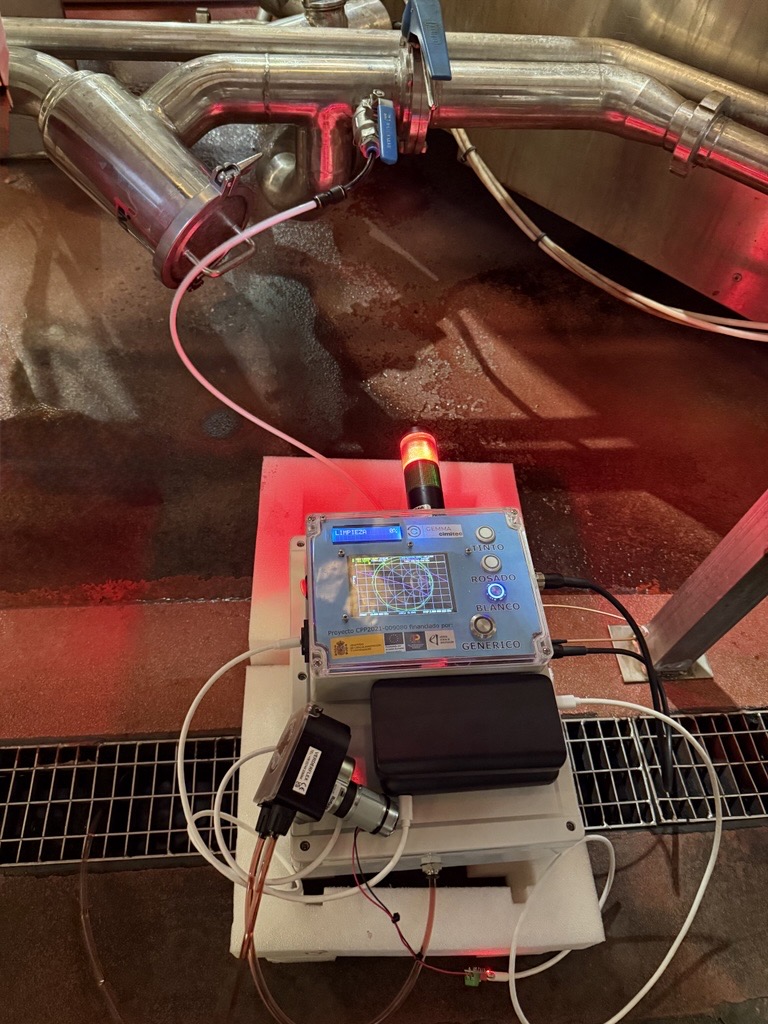

Smart Cellar Project

- Goal: Monitor Clean in Place process to reduce waste.

- Tech: Planar sensors integrated in pipes.

- Partner: Garcia Carrion - CPP Project.

Application: Agrifood

Smart Cellar Project

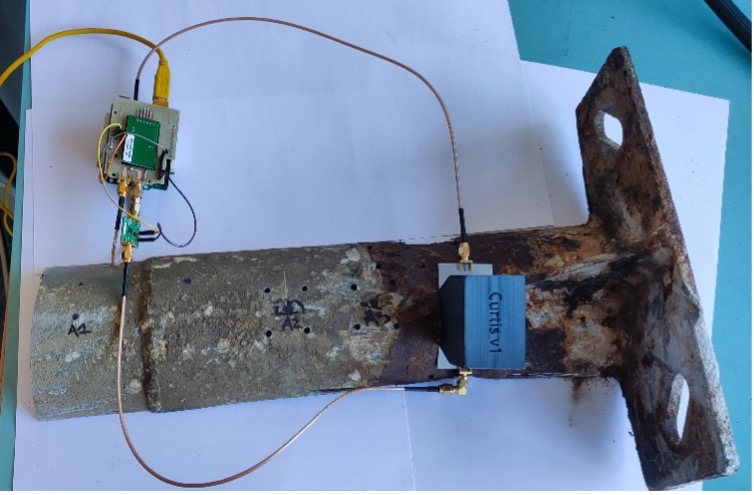

Application: Structural Health

Corrosion Detection

- Goal: Detect rust on street light poles.

- Tech: Resonance-Antiresonance sensors.

- Partner: RUBATEC.

Application: Remote Sensing

WiFi CSI Monitoring

- Goal: Use existing WiFi signals for sensing.

- Tech: AI analysis of Channel State Information.

- Outcome: Passive environmental monitoring.

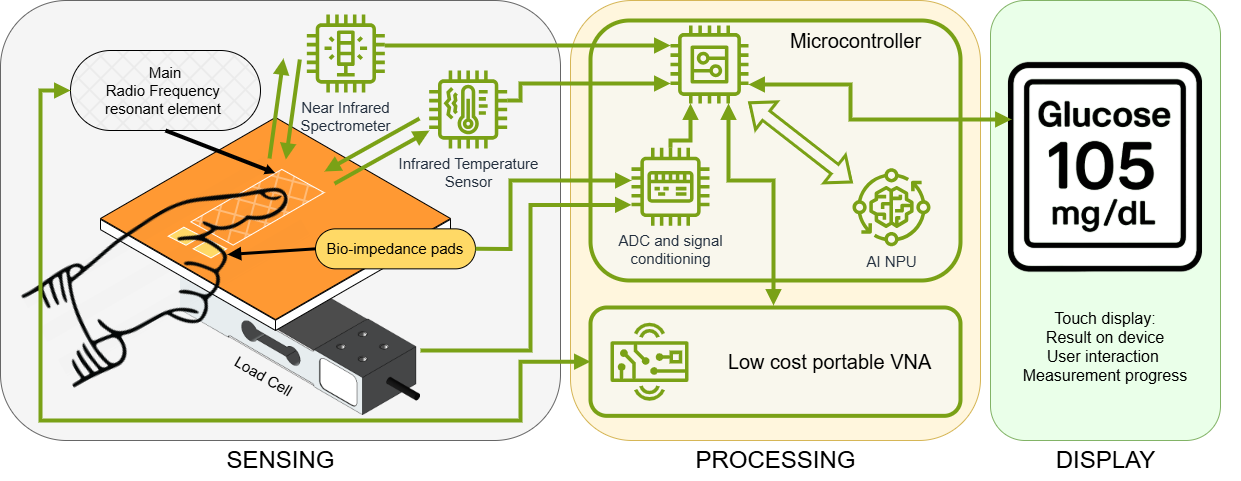

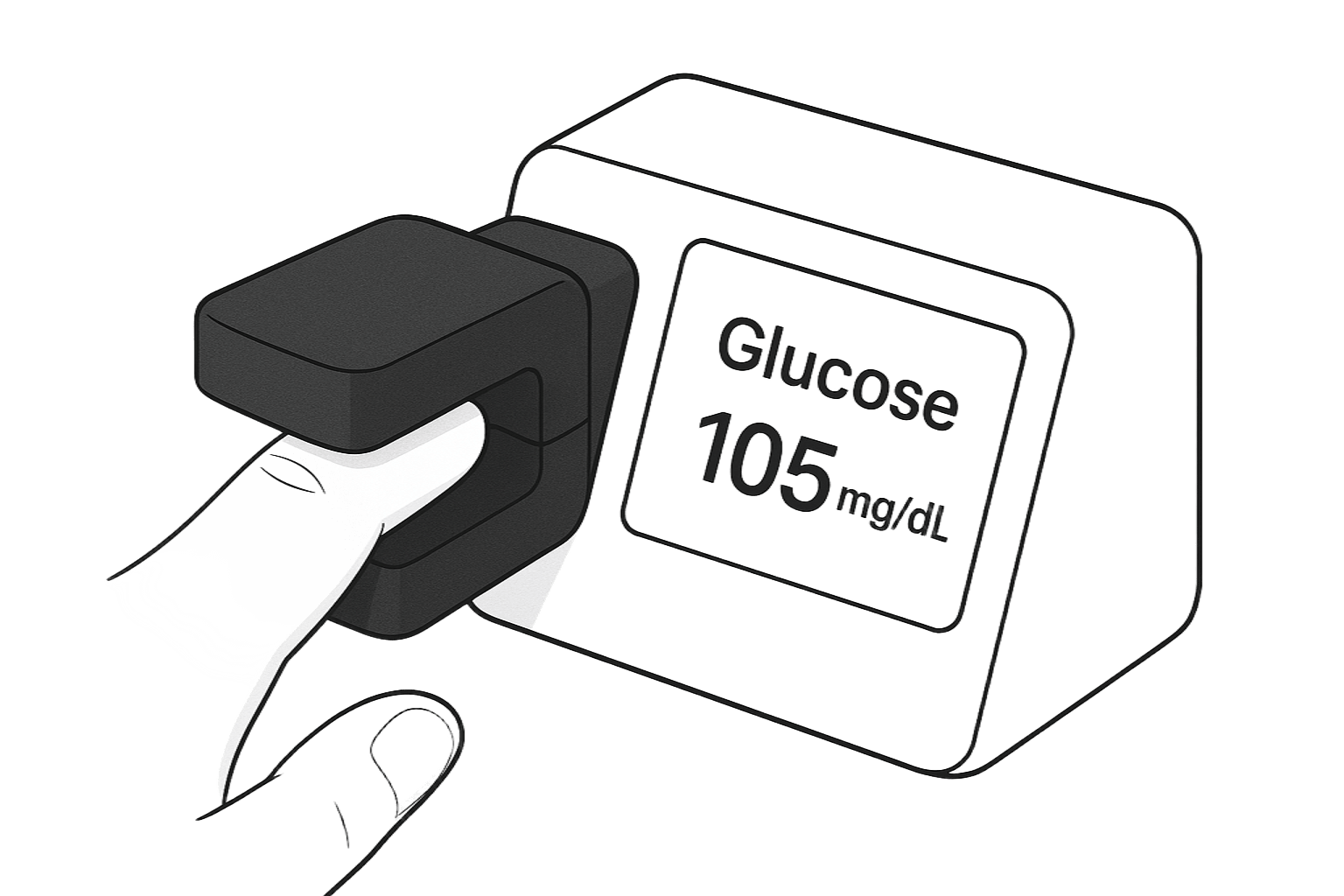

Application: Biomedical

Non-Invasive Glucose

- Goal: Non-invasive measurement of glucose in blood.

- Tech: Multi-Analyte sensor + Sensor Fusion + AI.

- Status: Proof of concept successful.

Future Work & Conclusions

Future Work: Immediate

Post-Doc Project

- Focus: Non-invasive Glucose Monitoring.

- Plan:

- In-vivo measurements.

- Clinical validation.

- Miniaturization.

Future Work: Long Term

- Generative AI Design: AI designing the sensor.

- Commodity Hardware: Sensing with smartphones/WiFi chips.

- Multi-modal Fusion: Combining microwave with optical/acoustic.

Conclusions

- Sensitivity: Maximized via phase-slope techniques (Inverters, Coupling, Loss).

- Methodology: From analytical design to AI-driven paradigm.

- Impact: Validated in real applications (Liquids, Remote, Bio).

A complete journey from fundamental physics to intelligent systems.

Acknowledgements

Thank you to:

- Prof. Ferran Martín

- GEMMA-CIMITEC Group

- Funding Agencies (FPU, CPP)

- Collaborators (UBC, RUBATEC, Garcia Carrion)

- Family & Friends